When every breath your team takes depends on the air you provide, there’s no margin for error. Whether you manage an industrial facility, a spray booth, or a confined-space operation, the safety and compliance of your breathing air system is non-negotiable.

At Griffin Air Systems, we understand that maintaining breathing air quality testing isn’t just a regulatory requirement – it’s a vital part of keeping your workforce healthy, productive, and protected. This article will help you understand the UK standards, testing procedures, and best practices for breathing air compressor air quality tests – and how the right breathing air quality test kit can keep you fully compliant.

Let’s break down what you need to know.

- What Is Breathing Air Quality Testing And Why Does It Matter?

- What UK Standards Govern Breathing Air Systems?

- How To Conduct A Breathing Air Compressor Air Quality Test

- What To Look For In A Breathing Air Quality Test Kit

- Common Issues Affecting Breathing Air Quality

- Maintenance And Monitoring Best Practices

- Key Takeaways For Breathing Air Quality Testing

What is Breathing Air Quality Testing and Why Does It Matter?

Breathing air quality testing ensures the air supplied to workers via a compressor is clean, safe, and free from harmful contaminants. These systems are used in many UK industries – from automotive paint booths and chemical plants to offshore platforms – wherever staff depend on compressed air for breathing.

Testing identifies issues like carbon monoxide, carbon dioxide, oil mist, or water vapour contamination that could cause serious health risks or system failure.

Why It Is Critical for UK Business

- Legal compliance with COSHH and BS EN 12021:2014

- Protection of staff against toxic gases, oil vapour, and oxygen deficiency

- Operational continuity – prevent system failures or shutdowns

- Audit assurance – documented test results support HSE inspections

Without regular testing, even minor leaks or filter failures can quickly compromise safety and compliance.

What UK Standards Govern Breathing Air Systems?

BS EN 12021:2014

The BS EN 12021:2014 is the main UK standard. This standard sets out the minimum quality requirements for compressed air used in breathing apparatus. It defines acceptable limits for contaminants:

| Parameter | Acceptable Range | Why It Matters |

| Oxygen | 21% ± 1 | Too low can cause dizziness or hypoxia |

| Carbon Monoxide (CO) | ≤ 5 ppm | Toxic and potentially fatal |

| Carbon Dioxide (CO₂) | ≤ 500 ppm | High levels can cause fatigue or unconsciousness |

| Oil Mist/Vapour | ≤ 0.5 mg/m³ | Can irritate lungs and clog filters |

| Water/Dewpoint | ≤ –11 °C | Prevents condensation and freezing in valves |

| Odour/Taste | None | Indicates contamination or poor filtration |

Control of Substances Hazardous to Health (COSHH) Regulations 2002

Under COSHH, employers have a clear duty to control exposure to substances hazardous to health, including gases, vapours, mists, and fumes that may contaminate breathing air systems.

For breathing air specifically, COSHH requires:

- A suitable and sufficient risk assessment identifying potential contaminants in compressed air supplies.

- Implementation of control measures to eliminate or reduce those risks – such as filtration, dryers, and regular breathing air quality testing.

- Ongoing monitoring and maintenance of control systems to ensure they continue to protect workers.

- Record-keeping to demonstrate compliance and the effectiveness of your controls during HSE inspections.

Failing to conduct breathing air tests or ignoring contaminated results could lead to enforcement action under COSHH, including fines or prohibition notices.

Management of Health and Safety at Work Regulations 1999

These health and safety regulations place a broader duty on employers to manage workplace risks. For companies operating breathing air systems, this means:

- Carrying out comprehensive risk assessments of all processes where breathing apparatus or compressed air is used.

- Ensuring competent persons design, test, and maintain breathing air systems.

- Establishing safe systems of work, including clear testing schedules, maintenance plans, and staff training.

- Reviewing risk assessments regularly – particularly after system changes, relocations, or maintenance.

Compliance isn’t a one-time exercise, it’s an ongoing management process that ensures every system remains safe under real-world conditions.

HSE Publication HSG53 – Respiratory Protective Equipment at Work

The HSE’s guidance document HSG53 (Respiratory Protective Equipment at Work) provides practical advice for selecting, using, and maintaining breathing air and respiratory protection systems.

Key points include:

- Selection: Choosing appropriate respiratory protective equipment (RPE) and breathing air sources based on risk assessments.

- Testing: Implementing regular breathing air quality testing to verify compliance with BS EN 12021:2014.

- Maintenance: Ensuring all compressors, filters, and dryers are maintained to prevent contamination and system failure.

- Competence: Only trained and authorised personnel should carry out air quality testing and system maintenance.

- Records: Employers must keep written test results and maintenance logs to demonstrate ongoing compliance.

HSG53 is not law itself, but it represents HSE-approved guidance. Following it is one of the most effective ways to demonstrate that you’re meeting your duties under UK health and safety law.

Putting It All Together

Taken together, COSHH, the Management of Health and Safety at Work Regulations, and HSG53 form the foundation of breathing air system compliance in the UK.

In practice, this means:

- Every breathing air system must be risk assessed, tested, and maintained regularly.

- Employers must keep detailed records of breathing air compressor air quality tests, including results and corrective actions.

- Only competent, trained individuals should carry out testing and interpret results.

- Non-compliance can lead to legal consequences, operational downtime, and – most importantly – serious risks to health.

By following these regulations and guidance documents, you not only meet legal obligations but also demonstrate a commitment to worker safety and operational excellence.

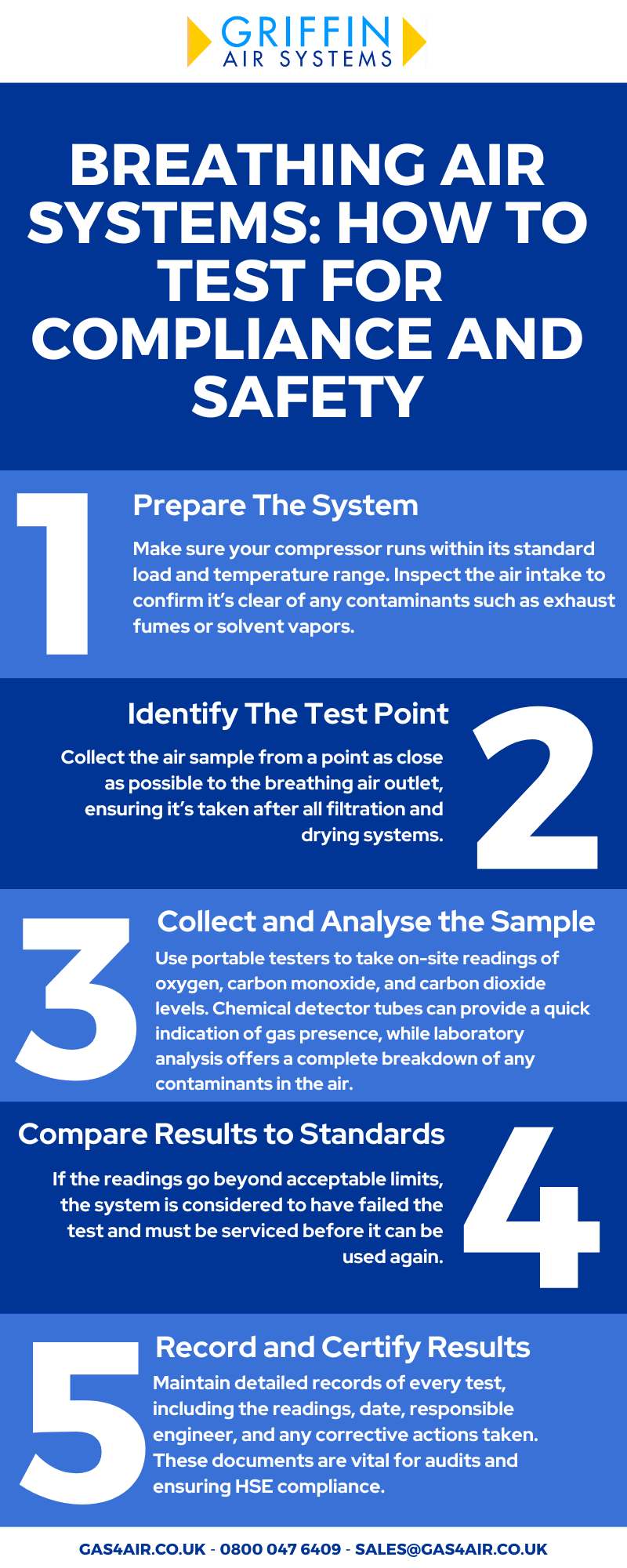

How to Conduct a Breathing Air Compressor Air Quality Test

Step 1: Prepare the System

Ensure your compressor operates under normal load and temperature. Check the intake is free from contamination sources like exhausts or solvents.

Step 2: Identify the Test Point

Sample air from as close as possible to the breathing air outlet – after all filtration and drying equipment.

Step 3: Collect and Analyse the Sample

You can use:

- Portable testers for on-site readings of oxygen, CO, and CO₂.

- Chemical detector tubes for quick indication of gas presence.

- Laboratory analysis for full breakdown of contaminants.

Step 4: Compare Results to BS EN 12021 Standards

If readings exceed acceptable limits, the system fails the test and must be serviced before use.

Step 5: Record and Certify Results

Keep documentation of each test, including readings, date, engineer, and corrective actions. These records are essential for audits and HSE compliance.

Testing Frequency in the UK

- Every 3 months minimum for fixed installations.

- After any relocation or modification of the compressor.

- Immediately after system maintenance or filter change.

Regular testing ensures consistent compliance and early detection of problems.

What to Look for in a Breathing Air Quality Test Kit

A reliable breathing air quality test kit allows engineers to assess air purity quickly and accurately. Features to consider:

- BS EN 12021 compliance for accurate readings.

- Detection range suitable for your industry (e.g., high-precision for offshore use).

- Calibration certificate for traceability.

- Ease of use – simple to operate and interpret results.

- Durability – robust enough for fieldwork.

Why Choose a Test Kit for Breathing Air Quality Monitoring?

Test kits provide immediate on-site results, ideal for routine checks between quarterly lab analyses. This proactive approach prevents downtime and ensures issues are caught early.

At Griffin Air Systems, we supply and maintain certified breathing air testing kits, and our engineers can train your team to use them safely and effectively.

Common Issues Affecting Breathing Air Quality

- Intake Contamination

If your compressor intake draws air near vehicle exhausts or chemical vents, harmful gases like CO can enter the system.

Solution: Relocate intakes and install pre-filters or CO monitors.

- Filter Degradation

Filters saturate over time, allowing oil mist or moisture through.

Solution: Replace filters at set intervals; never wait until efficiency drops.

- Dryer Malfunction

A failing dryer raises dewpoint, leading to condensation, corrosion, or freezing.

Solution: Monitor dewpoint regularly and service dryers before failure.

- Poor Record-Keeping

Lack of documentation can result in failed audits.

Solution: Keep detailed logs of every breathing air compressor air quality test and maintenance action.

- Inadequate Training

Operators unaware of system risks can overlook early warning signs.

Solution: Provide regular training and ensure only qualified engineers conduct tests.

Maintenance and Monitoring Best Practices

Design & Installation Tips

- Position compressor intakes away from potential contamination sources.

- Use a multi-stage filtration system: particulate → coalescing → activated carbon → desiccant → final filter.

- Include accessible test ports downstream of filtration.

Routine Monitoring

| Frequency | Task |

| Daily | Check filters, pressure, moisture traps |

| Weekly | Inspect compressor oil level and dryer condition |

| Monthly | Review dewpoint and temperature trends |

| Quarterly | Conduct full breathing air quality testing |

Training & Documentation

Ensure testing staff understand how to interpret readings and escalate issues. Keep signed and dated test reports for at least five years to satisfy HSE and insurance audits.

Working with an accredited service provider like Griffin Air Systems guarantees compliance, precision, and peace of mind.

Key Takeaways for Breathing Air Quality Testing

- Regular breathing air quality testing protects employees and ensures UK compliance.

- BS EN 12021:2014 defines contaminant limits and oxygen levels.

- Conduct a breathing air compressor air quality test at least quarterly or after any major change.

- Always use a certified breathing air quality test kit for accurate, traceable results.

- Maintain comprehensive records and act immediately on any test failure.

- Partner with experts like Griffin Air Systems for professional testing, maintenance, and compliance support.

FAQs

What is the purpose of breathing air testing?

Breathing air testing verifies that the air supplied to respirators or breathing apparatus is safe for human inhalation. It detects contaminants like carbon monoxide, oil vapour, and water, ensuring compliance with BS EN 12021 standards.

How often should breathing air quality testing be done?

Testing should be completed every three months, or more frequently if systems are mobile, newly installed, or used in high-risk environments such as chemical plants or offshore sites.

What happens if my system fails the air quality test?

If a test reveals contamination or non-compliance, isolate the system immediately. Replace filters, check the intake area, and retest before allowing use. Griffin Air Systems can provide rapid re-testing and root cause analysis to get you back online safely.

Protect Your People with Griffin Air Systems

At Griffin Air Systems, we’ve spent over 30 years helping UK businesses maintain safe, efficient, and compliant compressed air solutions. From breathing air quality testing and system design to full compressor maintenance programmes, our engineers deliver reliable, documented results.

Don’t wait until an inspection or incident exposes a problem. Book a breathing air compressor air quality test today and ensure your workforce is protected.

Contact us today to speak with our experts.

Related Articles

- Understanding ISO 8573 Air Quality Standards

- Air Compressor Maintenance 101: Keeping Your Machine Running Smoothly

- Do You Need an Air Dryer for Your Compressor?