Heat recovery from air compressors is one of the most effective and underused ways to improve energy efficiency in UK manufacturing and industrial facilities. In this guide, we explain how air compressor heat recovery works, why it matters, and how businesses can reduce waste heat and lower carbon emissions. If you’re looking to improve your air compressor energy systems, or upgrade to heat recovery compressed air systems, this article is for you.

As specialists in compressed air solutions, Griffin Air Systems supports UK organisations with efficient, reliable, and cost-saving system design and optimisation. Before we dive into the technical details, here’s what you’ll learn next.

Table of Contents:

- How Does Heat Recovery from Air Compressors Work?

- What Happens to the Heat Generated by Air Compressors?

- Benefits of Air Compressor Heat Recovery for UK Facilities

- Heat Recovery Methods for Compressed Air Systems

- How to Calculate Potential Energy Savings

- Common Applications of Heat Recovery in Industry

- How to Implement Heat Recovery in Your Air Compressor System.

How Does Heat Recovery from Air Compressors Work?

Heat recovery from air compressors works by capturing the thermal energy generated during compression and redirecting it to purposes such as space heating, water heating, or process heating. This reduces energy waste and lowers operating costs.

What Generates Heat in an Air Compressor?

All air compressors generate heat due to the thermodynamic process of compressing air. As air is squeezed into a smaller space, the temperature rises significantly. In fact, more than 90% of the electrical energy used to power an air compressor converts into heat.

Without a recovery system, most of this heat is released into the atmosphere and wasted.

How Heat Recovery Captures Usable Energy

Heat recovery systems attach to your compressor’s cooling system or oil circuit, capturing heat before it is dissipated. The recovered heat is then redirected through heat exchangers for reuse elsewhere in the facility.

This simple principle can reduce energy waste by up to 80%.

What Happens to the Heat Generated by Air Compressors?

The Fate of Waste Heat Without Recovery

In traditional setups, waste heat is lost through:

- Compressor cooling fans

- Oil coolers

- Aftercoolers

- Hot air exhaust

This heat often warms compressor rooms unnecessarily, requiring extra ventilation or cooling to keep systems stable.

Redirecting Waste Heat for Productive Use

With air compressor heat recovery, this lost heat is repurposed. For example:

- Hot air can be ducted for space heating

- Hot water can supplement industrial cleaning or washdown

- Pre-heating boiler feedwater reduces fuel consumption

Heat recovery transforms a by-product into a valuable energy asset.

Benefits of Air Compressor Heat Recovery for UK Facilities

Reduce Energy Costs Immediately

The most significant benefit is cost reduction. Recovered heat can replace energy normally generated by gas, oil, or electricity.

Businesses regularly report annual savings of 10–25% on heating bills.

Lower Carbon Emissions

Decarbonisation is a major priority across the UK industrial sector. Reusing waste heat helps you:

- Cut CO₂ emissions

- Meet sustainability targets

- Align with ISO 50001 energy management standards

Extend Compressor Life

Heat recovery systems stabilise compressor temperatures by improving cooling efficiency. This contributes to:

- Reduced wear

- Longer service life

- Lower maintenance costs

Improve Return on Investment (ROI)

Most heat recovery retrofits pay for themselves within 6–18 months, depending on site demand for heat and compressor utilisation.

Heat Recovery Methods for Compressed Air Systems

1. Hot Air Recovery

Hot air recovery is the simplest method and involves ducting warm compressor exhaust air to a designated space.

How Hot Air Recovery Works

A ducting system is connected to the compressor’s cooling air outlet. During cold months, warm air is channelled into production spaces, warehouses, or workshops. A bypass damper releases warm air outdoors during warmer months.

Ideal Uses

- Space heating for workshops

- Reducing reliance on electric heaters

- Preventing frost in storage areas

2. Hot Water Recovery from Oil-Cooled Compressors (H2)

Oil-injected screw compressors produce hot oil as a by-product. This heat can be extracted to warm water.

How It Works

A heat exchanger is installed on the compressor’s oil circuit, enabling water to absorb heat from hot oil before circulating to:

- Washdown stations

- Radiators

- Process heating systems

- Boiler pre-heating

Typical Water Temperature Output

Most systems can produce water at 60–90°C, ample for sanitary hot water and many industrial processes.

3. Heat Recovery from Aftercoolers

Aftercoolers are designed to cool compressed air before it enters downstream equipment.

Potential for Recovery

Although less common than oil circuit recovery, aftercooler heat can be used for:

- Pre-heating ventilation air

- Supporting central heating loops

How to Calculate Potential Energy Savings

Step-by-Step Process

- Determine Compressor Power (kW) – e.g., 75 kW.

- Estimate Recoverable Heat – usually 70–90% of input power.

- Calculate Operating Hours – e.g., 3,000 hours/year.

- Multiply to Estimate Available Heat Energy.

- Compare Against Heating Fuel Costs (gas, electricity, oil).

Example Calculation

A 75 kW compressor running 3,000 hours per year:

- Recoverable heat: approx. 75 kW × 0.8 = 60 kW

- Annual heat available: 60 kW × 3,000 = 180,000 kWh

If gas costs 10p per kWh:

- Savings = 180,000 × £0.10 = £18,000 per year

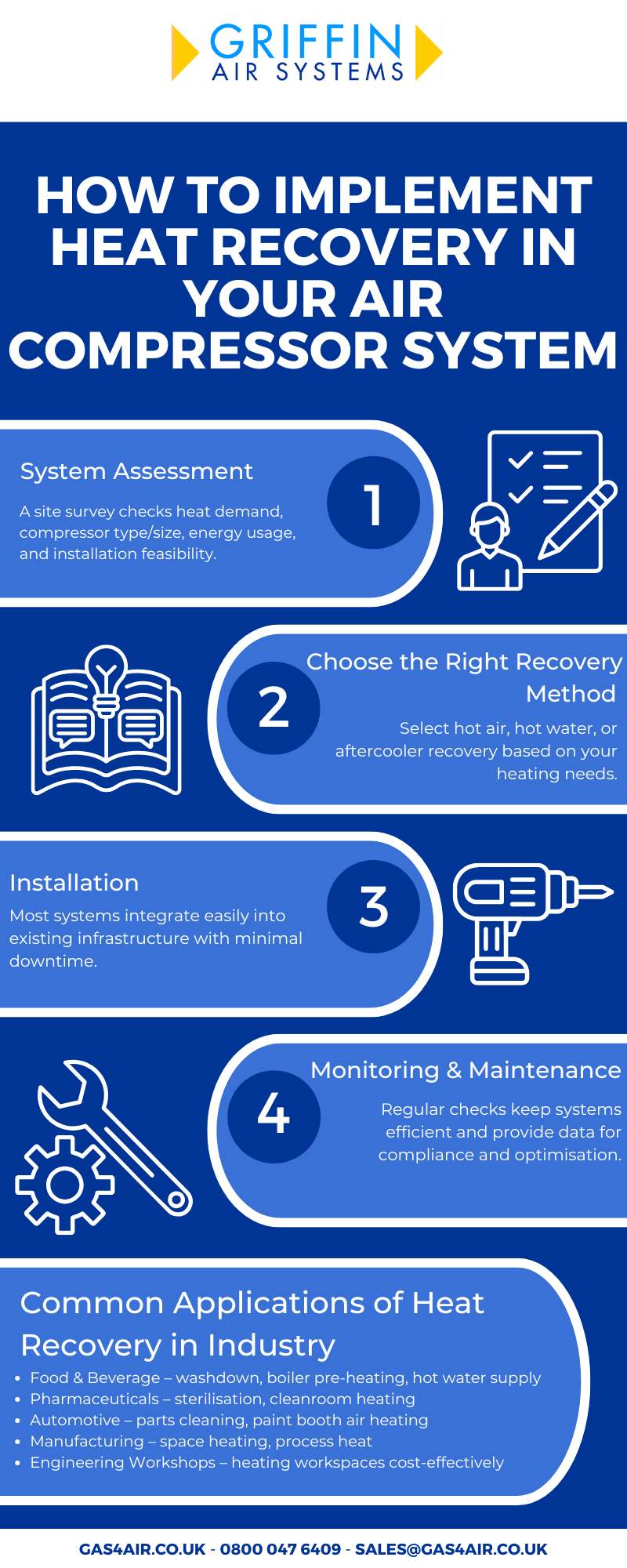

Common Applications of Heat Recovery in Industry

Industries across the UK benefit from heat recovery compressed air systems, including:

- Food & Beverage – washdown, boiler pre-heating, hot water supply

- Pharmaceuticals – sterilisation, cleanroom heating

- Automotive – parts cleaning, paint booth air heating

- Manufacturing – space heating, process heat

- Engineering Workshops – heating workspaces cost-effectively

How to Implement Heat Recovery in Your Air Compressor System

Step 1: System Assessment (H3)

A site survey determines:

- Heat demand

- Compressor size and type

- Current energy usage

- Installation feasibility

Step 2: Choose the Right Recovery Method (H3)

Griffin Air Systems recommends:

- Hot air recovery for space heating

- Hot water recovery for processes requiring warm water

- Aftercooler recovery for supplementary heating

Step 3: Installation (H3)

Most systems integrate easily into existing infrastructure with minimal downtime.

Step 4: Monitoring & Maintenance (H3)

Regular system checks ensure heat exchangers and ducting operate efficiently. Monitoring also provides data for ISO compliance and ongoing optimisation.

Key Takeaways for Air Compressor Heat Recovery

- Up to 90% of air compressor energy becomes heat — most of which can be reused.

- Heat recovery reduces energy bills, carbon emissions, and waste.

- Options include hot air recovery, hot water recovery, and aftercooler recovery.

- Typical ROI is 6–18 months.

- Suitable for most industrial sectors, especially those with heat or hot water demand.

- Griffin Air Systems provides UK-wide design, installation, and optimisation services.

Frequently Asked Questions

What is the heat recovery on an air compressor?

Heat recovery on an air compressor is the process of capturing the waste heat produced during air compression and reusing it for space heating, hot water, or process heat. This allows air compressor heat recovery systems to reclaim up to 90% of input energy, improving the efficiency of your air compressor energy systems and reducing waste.

Does a heat recovery system use a lot of electricity?

No, heat recovery systems use very little electricity because they simply redirect existing air compressor heat through heat exchangers or ducting. This makes heat recovery compressed air systems highly efficient, helping cut overall energy use rather than increase it.

Is a heat recovery system worth it?

Yes, heat recovery systems are very cost-effective. By turning waste heat into usable energy, air compressor heat recovery can deliver rapid ROI and reduce heating costs and emissions. For most facilities with heat or hot water demand, it’s a highly worthwhile upgrade to air compressor energy systems.

Improve Energy Efficiency with Griffin Air Systems

Improving energy efficiency is no longer optional for UK businesses, it’s essential for reducing operating costs and meeting sustainability goals. Heat recovery from air compressors offers one of the quickest and most cost-effective ways to achieve both.

By capturing and reusing waste heat, your business can unlock major savings, lower emissions, and extend the life of your compressed air equipment.

Ready to optimise your air compressor energy system? Contact Griffin Air Systems today for expert advice, system upgrades, or a full heat recovery installation.

Explore our compressed air services or get in touch via our Contact page to get started.