Air compressor pressure drops are one of the most common, and costly, issues faced by businesses relying on compressed air systems across the UK. Whether you’re experiencing air compressor low pressure at point of use or inconsistent air pressure in pipes, these problems can reduce efficiency, damage equipment and increase energy bills.

In this expert guide from Griffin Air Systems, we explain why air compressor pressure drops happen, how they affect the pressure of compressed air, and, most importantly, how to fix them using proven engineering solutions. Read on to understand the root causes and practical remedies before small pressure losses turn into major operational issues.

Table of Contents:

- Why Does Air Compressor Pressure Drop Occur?

- How Air Pressure in Pipes Impacts System Performance

- Common Causes of Air Compressor Low Pressure

- How to Diagnose Pressure Drops in Compressed Air Systems

- How to Fix Air Compressor Pressure Drop Problems

- Preventing Future Pressure Drops in Compressed Air Systems

- Key Takeaways for Air Compressor Pressure Drop

Why Does Air Compressor Pressure Drop Occur?

Air compressor pressure drop occurs when the pressure of compressed air decreases between the compressor and the point of use. In simple terms, your compressor may be producing enough pressure, but your system is losing it along the way.

Pressure drops matter because compressed air is an energy-intensive utility. Even a 1 bar pressure drop can increase energy consumption by up to 7%, driving up operating costs and reducing equipment performance across manufacturing, automotive, food production and engineering environments.

What Is a Pressure Drop in Compressed Air Systems?

A pressure drop is the difference between the pressure generated at the compressor outlet and the pressure available at the application point.

This loss typically happens due to:

- Resistance in pipework

- Air leaks

- Undersized components

- Poor system design

Left unchecked, pressure drops force compressors to work harder, shortening equipment lifespan and increasing downtime.

How Air Pressure in Pipes Impacts System Performance

Air pressure in pipes plays a critical role in determining how efficiently compressed air is delivered throughout your facility.

Why Pipework Design Matters

Pipework that is too small, poorly routed, or corroded creates friction within the system. This friction slows airflow and reduces the usable pressure available at the point of use. Pressure drop can be caused by long pipe runs, multiple bends and elbows, undersized pipe diameters, and the presence of rust, scale, or other internal contamination. A well-designed compressed air distribution system minimises these losses, ensuring tools and machinery receive a consistent and reliable airflow.

Learn more on our Compressed Air Pipework Installation page.

Common Causes of Air Compressor Low Pressure

Air compressor low pressure issues rarely stem from a single fault. More often, multiple inefficiencies combine to reduce system performance.

Air Leaks: The Silent Pressure Killer

Air leaks are the number one cause of pressure drop in compressed air systems. Even small leaks can result in substantial air loss over time.

Common leak points include:

- Hose couplings

- Quick-release fittings

- Drain valves

- Flange connections

A single 3mm leak at 7 bar can cost thousands of pounds annually in wasted energy.

Explore our Leak Detection & Air Audits service

Undersized Pipework and Components

If pipes, filters, dryers or regulators are too small for system demand, pressure loss is inevitable.

Symptoms include:

- Pressure falling during peak demand

- Tools starving for air

- Compressor running continuously

Correct component sizing is essential to maintain stable pressure of compressed air throughout your system.

Blocked or Poorly Maintained Filters

Clogged air filters restrict airflow and increase pressure drop across the system.

Signs of filter-related pressure loss:

- Pressure difference before and after filters

- Increased compressor load

- Reduced air quality

Routine servicing and timely filter replacement can prevent unnecessary pressure loss.

See our Air Compressor Servicing & Maintenance solutions

Inadequate Compressor Capacity

Sometimes the compressor itself is the issue. If system demand exceeds compressor output, pressure drops will occur no matter how efficient the pipework is.

This often happens when:

- Production expands without system upgrades

- New equipment is added

- Compressors are operating beyond their duty cycle

How to Diagnose Pressure Drops in Compressed Air Systems

Identifying the cause of pressure drop is the first step toward fixing it effectively.

Step-by-Step Pressure Drop Diagnosis

- Measure pressure at the compressor outlet

- Measure pressure at key points along the system

- Compare pressure at the point of use

- Identify where the largest pressure loss occurs

A pressure drop greater than 0.3 bar between compressor and application should be investigated.

Using Compressed Air Audits

Professional compressed air audits provide a detailed analysis of:

- System demand

- Leak rates

- Pressure losses

- Energy efficiency

Audits are one of the fastest ways to pinpoint why air compressor pressure drops happen and how to resolve them cost-effectively.

Book a Compressed Air Audit with Griffin Air Systems.

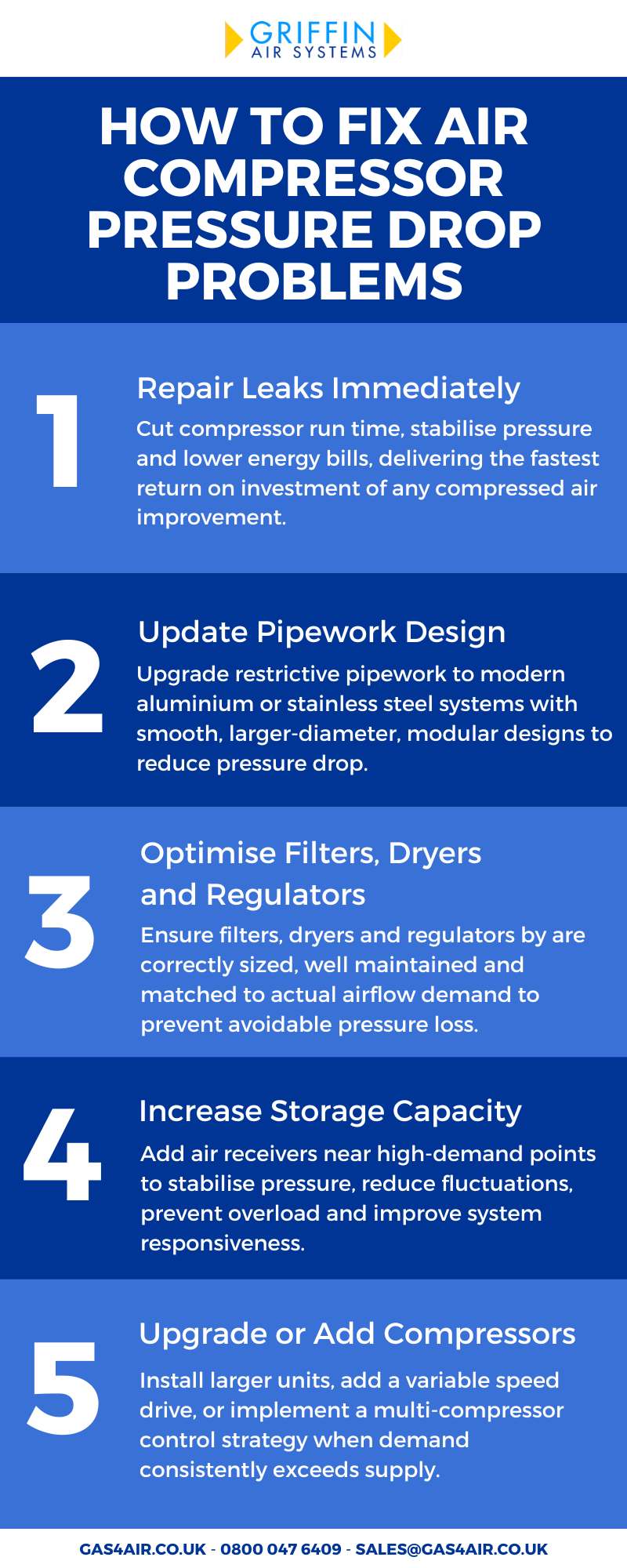

How to Fix Air Compressor Pressure Drop Problems

Once the cause is identified, targeted solutions can restore optimal air pressure in pipes and reduce wasted energy.

Repair Air Leaks Immediately

Fixing leaks delivers the fastest return on investment of any compressed air improvement.

Benefits include:

- Improved pressure stability

- Reduced compressor run time

- Lower energy bills

Upgrade Pipework Design

Replacing restrictive pipework with modern aluminium or stainless steel systems can dramatically reduce pressure drop.

Advantages of upgraded pipework:

- Smooth internal surfaces

- Larger internal diameters

- Modular, future-proof layouts

Optimise Filters, Dryers and Regulators

Ensure all downstream equipment is:

- Correctly sized

- Properly maintained

- Matched to actual airflow demand

Incorrectly sized air treatment equipment is a common but avoidable cause of pressure loss.

Increase Storage Capacity

Adding air receivers near high-demand applications helps stabilise pressure during peak usage.

Additional storage:

- Reduces pressure fluctuations

- Prevents compressor overload

- Improves system responsiveness

Upgrade or Add Compressors

If demand consistently exceeds supply, a system upgrade may be required. This could involve:

- Installing a larger compressor

- Adding a variable speed drive (VSD) unit

- Creating a multi-compressor control strategy

View our Industrial Air Compressors range.

Preventing Future Pressure Drops in Compressed Air Systems

Prevention is always more cost-effective than reactive repairs.

Implement Planned Maintenance

Regular servicing ensures:

- Filters remain clean

- Leaks are detected early

- Components operate at peak efficiency

Monitor System Pressure Continuously

Pressure sensors and monitoring systems provide real-time insights into system performance and highlight developing issues before they escalate.

Design for Future Demand

Compressed air systems should always include capacity for growth. Oversights during initial design often lead to chronic air compressor low pressure problems later.

Key Takeaways for Air Compressor Pressure Drop

- Air compressor pressure drops reduce efficiency and increase energy costs

- Air leaks are the most common cause of pressure loss

- Poor pipework design significantly impacts air pressure in pipes

- Correct sizing of compressors and components is critical

- Professional audits provide the clearest route to long-term solutions

- Preventative maintenance is the best defence against pressure problems

FAQs

What causes air compressor low pressure?

Air compressor low pressure is usually caused by air leaks, undersized pipework, clogged filters or insufficient compressor capacity. Identifying the weakest point in the system is key to resolving the issue permanently.

How much pressure drop is acceptable in compressed air systems?

In most industrial systems, a pressure drop of no more than 0.3 bar between the compressor and point of use is recommended. Anything higher indicates inefficiency or system faults.

Can air pressure in pipes affect energy consumption?

Yes, reduced air pressure in pipes forces compressors to work harder and run longer, significantly increasing energy usage and operating costs.

Fix Pressure Problems with Griffin Air Systems

Air compressor pressure drops are not just an inconvenience, they are a clear sign that your compressed air system is wasting energy and underperforming. By understanding why these issues occur and how to fix them, businesses can restore efficiency, reliability and cost control.

Griffin Air Systems specialises in the design, supply, installation and maintenance of compressed air systems across the UK. From leak detection and pipework upgrades to complete system optimisation, our experts deliver solutions that keep your pressure exactly where it should be.

Contact us today to book an audit or discuss your compressed air requirements.