Compressed air is one of the most expensive utilities in industry, yet it is also one of the most overlooked when it comes to energy efficiency. Even a small air compressor leak can waste thousands of pounds in electricity every year. For UK manufacturers, workshops, and facilities management teams, mastering compressed air leak detection is essential to keeping costs down, productivity high, and operations sustainable.

In this article, we’ll cover the most common types of air compressor leaks, how to spot them using methods such as ultrasonic leak detectors, and the best steps to stop air compressor leaks for good.

Whether you manage a single compressor in a workshop or oversee a complex manufacturing facility, this guide will give you actionable solutions to improve reliability and efficiency.

- Why Compressed Air Leaks Are a Serious Problem

- 10 Common Compressed Air Leaks (And How to Fix Them)

- How to Detect Compressed Air Leaks Effectively

- Best Practices to Stop Air Compressor Leaks for Good

- Key Takeaways for Air Compressor Leaks

- Frequently Asked Questions

Why Compressed Air Leaks Are a Serious Problem

Compressed air leaks are not just an inconvenience – they are a financial drain. Studies suggest that 20–30% of all compressed air generated in UK facilities is lost through leaks.

That means if your business spends £10,000 annually on compressed air, up to £3,000 could literally be escaping into thin air.

Beyond cost, air compressor leaks lead to:

- Increased compressor running hours, shortening equipment life.

- Pressure drops that reduce tool efficiency and production quality.

- Higher carbon footprint and wasted energy.

By investing in compressed air leak detection and repair, companies can significantly cut operating costs while also meeting sustainability targets.

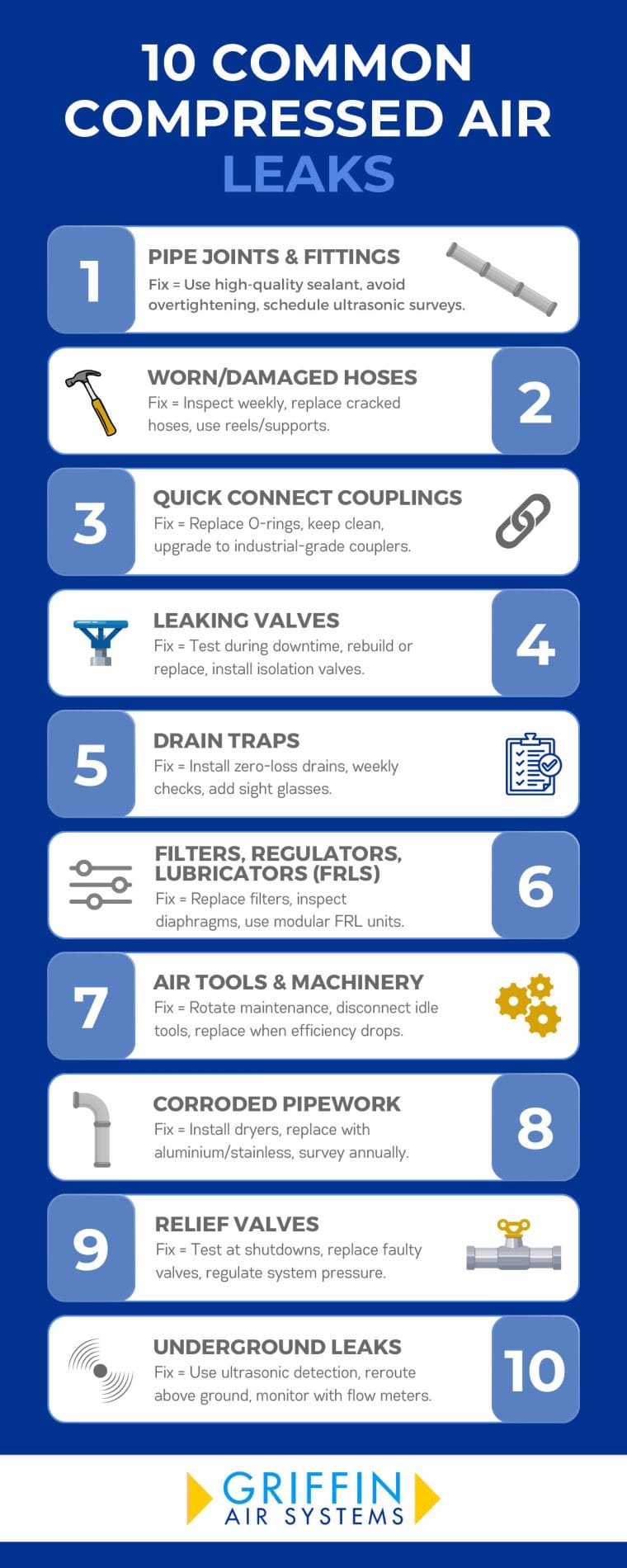

10 Common Compressed Air Leaks & How to Fix Them

Below are the 10 most common sources of air compressor leaks in UK industrial and commercial settings, along with practical advice on how to stop them.

1. Leaking Pipe Joints and Fittings

Pipe joints are one of the most vulnerable points in any compressed air system. Over time, vibration, poor installation, or thermal expansion can cause even well-sealed joints to loosen. Threaded connections in particular are notorious for air leakage.

How to fix:

- Use high-quality thread sealant rather than over-tightening joints.

- Consider switching to welded, brazed, or compression fittings, which are more durable in high-pressure systems.

- Introduce regular leak surveys with ultrasonic leak detectors to catch problems before they escalate.

2. Worn or Damaged Hoses

Hoses endure constant movement, bending, and exposure to oils and chemicals. Small cracks can quickly grow into major leaks if unnoticed. This problem is especially common in production lines where tools are moved frequently.

How to fix:

- Inspect hoses weekly and replace any showing cracks or abrasions.

- Store hoses properly when not in use to avoid unnecessary stress.

- Invest in hose reels or supports to reduce wear from dragging.

3. Faulty Quick Connect Couplings

Quick couplers make life easier, but if their O-rings dry out or wear, they leak even when connected. In a busy shop floor, hundreds of connections may be in play at once — which means multiple small leaks adding up to significant losses.

How to fix:

- Replace O-rings at scheduled intervals, not just when they fail.

- Keep couplings clean; dust and grit accelerate wear.

- Upgrade to modern, leak-resistant couplings designed for heavy industrial use.

4. Leaking Valves

Valves control air flow, but when internal seals wear, they may not shut off completely. The result? Continuous bleeding of air even when a line is supposedly “off”.

How to fix:

- Test valves during downtime: if pressure continues to drop, the valve may be leaking.

- For older valves, consider rebuilding kits instead of replacements.

- Install isolation valves so sections of the system can be shut off for repair without downtime across the plant.

5. Open or Faulty Drain Traps

Condensate drains prevent water from collecting in the system. Unfortunately, mechanical float drains often stick open – causing a continuous hiss of escaping compressed air.

How to fix:

- Inspect drains weekly for proper operation.

- Install zero-loss electronic drains which only open when needed, preventing waste.

- Fit drains with sight glasses so operators can check function at a glance.

6. Leaks in Filters, Regulators, and Lubricators (FRLs)

FRL units ensure air is clean, dry, and properly conditioned. However, cracked housings, clogged filters, and aged seals can cause persistent leaks.

How to fix:

- Replace filter elements regularly; clogged filters increase backpressure and force leaks.

- Check regulator diaphragms, as small tears can bleed air unnoticed.

- Consider modular FRL systems that allow quick, tool-free servicing.

7. Leaking Air Tools and Machinery

Tools such as impact wrenches, sanders, or pneumatic presses often develop internal leaks after years of use. Even idle tools left connected may slowly release air.

How to fix:

- Create a maintenance rotation for tools, including gasket and seal replacement.

- Store tools disconnected when not in use.

- Weigh up replacement versus repair – sometimes a new energy-efficient tool saves more in the long run.

8. Corroded or Cracked Pipework

Older systems, especially those using galvanised or black iron pipe, are prone to corrosion from moisture in the compressed air. Corrosion leads to pinholes and cracks, which can spread throughout the network.

How to fix:

- Install dryers to control moisture levels.

- Replace outdated steel with aluminium or stainless steel, which resist corrosion.

- Conduct annual pipe surveys and record findings for predictive maintenance.

9. Pressure Relief Valve Leaks

Relief valves are a safety requirement, but when poorly maintained they can stick partially open. Not only does this waste energy, but it also compromises safety if the system cannot hold correct pressure.

How to fix:

- Test valves during scheduled shutdowns.

- Replace faulty relief valves immediately; never attempt to block or “plug” a leaking valve.

- Make sure system pressure is correctly regulated to prevent valves lifting unnecessarily.

10. Hidden Underground or In-Wall Leaks

Some of the hardest leaks to find occur in buried pipework or behind walls. Symptoms include unexplained pressure drops, compressors running more frequently, or tools losing efficiency.

How to fix:

- Use ultrasonic leak detection equipment to pinpoint leaks otherwise impossible to hear.

- Where possible, reroute pipes above ground for easier maintenance.

- Introduce flow meters to track air consumption and identify discrepancies between zones.

How to Detect Compressed Air Leaks Effectively

Detecting leaks is just as important as fixing them. Here are the three most effective methods:

Visual and Manual Checks

Walkthrough inspections can reveal obvious leaks such as hissing sounds, damaged hoses, or excessive tool vibration. While simple, this method often misses smaller leaks.

Soapy Water Tests

Applying soapy water to suspected leak points creates bubbles where air is escaping. This is effective for joints and fittings but impractical for large systems.

Ultrasonic Leak Detection

An ultrasonic leak detector is the gold standard for compressed air leak detection. It identifies leaks by picking up high-frequency sounds outside the range of human hearing.

Benefits of ultrasonic leak detection include:

- Detecting leaks in noisy environments.

- Pinpointing leaks invisible to the eye.

- Providing data for predictive maintenance.

Best Practices to Stop Air Compressor Leaks for Good

While quick fixes can temporarily solve compressed air leaks, the only way to minimise them long-term is to adopt a structured leak management programme. For businesses, this means combining proactive maintenance with the right tools, training, and expert support.

At Griffin, we specialise in helping companies implement exactly this kind of programme, ensuring your compressed air system operates at peak efficiency.

Here are the best practices we recommend:

- Regular Maintenance – Schedule inspections and servicing.

- Leak Tagging and Logging – Record leak locations and repairs for trend analysis.

- System Upgrades – Invest in energy-efficient pipework, drains, and couplings.

- Employee Training – Train staff to recognise and report leaks.

- Partner with Experts – Work with compressed air specialists like Griffin for professional leak detection and repair.

Work with Compressed Air Specialists like Griffin

While internal efforts are important, the most effective leak management comes from partnering with a specialist. This ensures that detection is accurate, repairs are reliable, and improvements are long-lasting.

At Griffin, we:

- Use state-of-the-art ultrasonic leak detectors to locate leaks that human senses can’t detect.

- Provide detailed cost analysis reports, showing how much money and energy you save by fixing each leak.

- Deliver end-to-end solutions – from identifying leaks, to repairing them, to upgrading your system for long-term performance.

- Offer UK-wide support, with engineers who understand the challenges of local industries from manufacturing to logistics.

By working with Griffin, you gain more than leak detection, you gain a partner committed to maximising efficiency, reducing costs, and supporting your sustainability goals.

Key Takeaways for Air Compressor Leaks

- Leaks waste 20–30% of compressed air in many UK facilities, costing thousands annually.

- The most common leaks are in joints, hoses, couplings, valves, drains, FRLs, tools, pipework, and relief valves.

- Ultrasonic leak detection is the most accurate way to find leaks, even in noisy or hidden areas.

- Long-term prevention needs a planned leak management programme: maintenance, logging, upgrades, and staff training.

FAQs

How do I know if my air compressor has a leak?

You can identify an air compressor leak by listening for hissing sounds, checking pressure drops when equipment is idle, or using leak detection tools such as ultrasonic devices.

What is the best way to find air compressor leaks?

The most effective method is using an ultrasonic leak detector, which identifies high-frequency sounds from leaks even in noisy factory environments.

How much do compressed air leaks cost UK businesses?

Compressed air leaks can cost UK businesses thousands each year. A single 3mm hole can waste more than £700 in electricity annually, depending on system pressure and running hours.

Stop Air Compressor Leaks with Griffin

Compressed air is too valuable to waste. By addressing leaks in joints, hoses, valves, and pipework, businesses can reduce costs, extend equipment life, and meet sustainability goals.

At Griffin, we specialise in compressed air leak detection and repair across the UK, using advanced ultrasonic technology to save our clients money and energy. Contact our friendly team today to learn more!