When choosing an air compressor, one of the first decisions you’ll face is whether to opt for an oil air compressor or an oil free air compressor. This crucial choice can significantly affect your equipment’s performance, maintenance schedule, longevity, and even your industry compliance.

Whether you’re running a food production line, a dental clinic, or a workshop, understanding the pros and cons of oil vs oil free air compressors will help you make an informed investment. At Griffin Air Systems, we provide both oil lubricated and oilless air compressors tailored to your business needs.

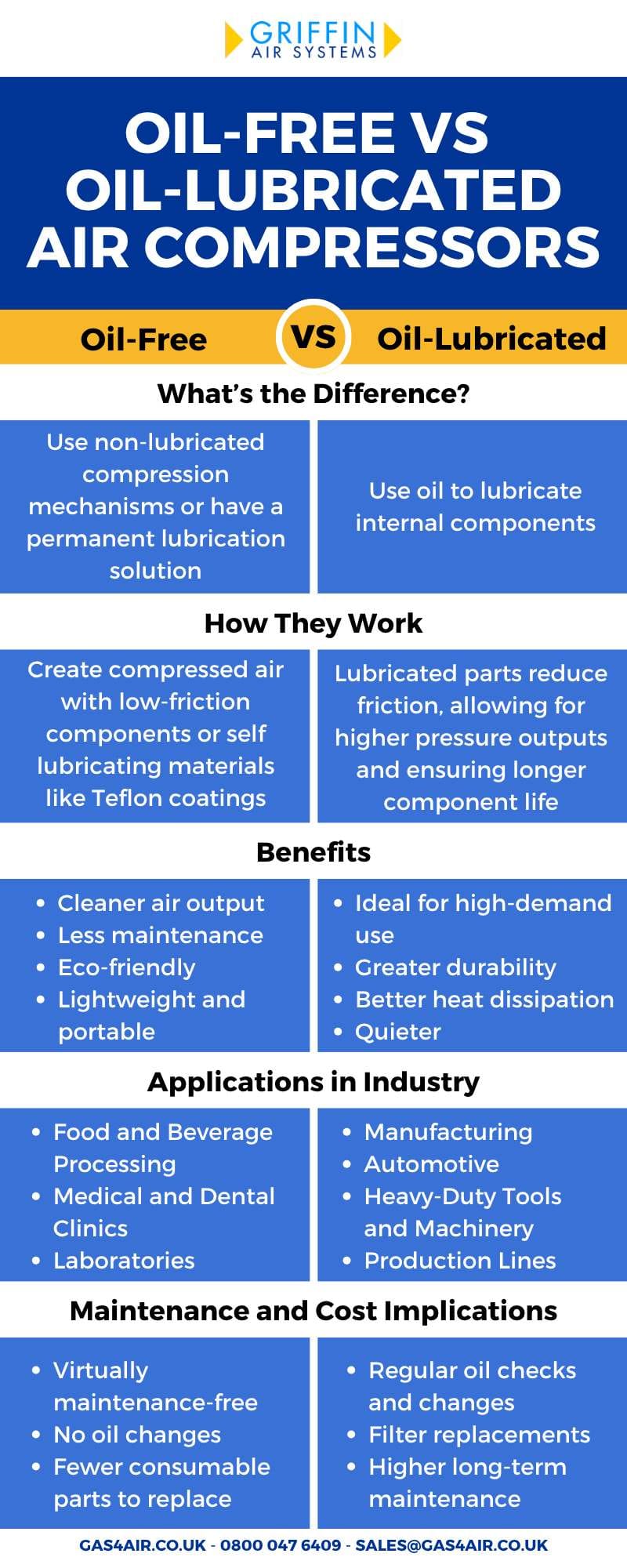

- Oil Air Compressor vs Oil Free: What’s the Difference?

- How Oil Lubricated Air Compressors Work

- How Oil Free Air Compressors Work

- Comparing Performance: Oil vs Oil Free Air Compressors

- Applications and Industry Use Cases

- Maintenance and Cost Implications

- Noise, Lifespan, and Environmental Impact

- Key Takeaways for Oil vs Oil Free Air Compressor

- FAQs

Oil Air Compressor vs Oil Free: What’s the Difference?

The fundamental difference lies in the lubrication method:

- Oil air compressors use oil to lubricate internal components.

- Oil free air compressors use non-lubricated compression mechanisms or have a permanent lubrication solution that doesn’t require oil top-ups.

Understanding this difference helps you determine which suits your budget, usage, and environment.

How Oil Lubricated Air Compressors Work

Oil air compressors use oil as a lubricant for the pump’s moving parts. This reduces friction, allows higher pressure outputs, and ensures longer component life.

Benefits of Oil Air Compressors

- Ideal for high-demand and continuous-use environments

- Greater durability due to less wear

- Better heat dissipation

- Quieter than most oil free models

Drawbacks of Oil Air Compressors

- Require regular oil changes

- Risk of oil carryover in compressed air (needs filtration)

- Not suitable for clean air applications like food or medical sectors

How Oil Free Air Compressors Work

Oil free air compressors eliminate the need for oil-based lubrication. These machines either rely on self-lubricating materials (like Teflon coatings) or are designed with low-friction components.

Benefits of Oil Free Air Compressors

- Cleaner air output – ideal for food, pharmaceutical, and medical use

- Less maintenance (no oil changes)

- Environmentally friendly

- Lightweight and often portable

Drawbacks of Oil Free Air Compressors

- Shorter lifespan compared to oil-lubricated models

- Noisier due to lack of dampening oil

- Lower maximum pressure capabilities

Comparing Performance: Oil vs Oil Free Air Compressors

| Feature | Oil Air Compressor | Oil Free Air Compressor |

| Durability | High | Moderate |

| Maintenance | Moderate to High | Low |

| Air Purity | Requires filtration | Naturally clean |

| Operating Noise | Quieter | Louder |

| Cost | Higher upfront + upkeep | Lower upfront, less upkeep |

| Lifespan | Longer | Shorter |

| Portability | Less portable | More portable |

Applications and Industry Use Cases

Different air compressor types are better suited to specific environments and tasks — here’s a breakdown of where oil and oil free compressors perform best:

Ideal Uses for Oil Lubricated Compressors

- Manufacturing and automotive

- Heavy-duty tools and machinery

- Workshops and production lines

These compressors are perfect for demanding environments where performance, reliability, and long operating cycles are essential.

Ideal Uses for Oil Free Air Compressors

- Food and beverage processing

- Medical and dental clinics

- Laboratories and electronics

Oil free air compressors are the go-to choice for environments where air purity is critical.

At Griffin Air Systems, we stock a wide range of both oil lubricated and oil free air compressors suitable for every use case.

Maintenance and Cost Implications

Beyond performance, it’s essential to consider how much time and money each air compressor type will require to keep running efficiently.

Oil Air Compressors

- Regular oil checks and changes

- Filter replacements to handle oil vapours

- Higher long-term maintenance costs

Oil Free Air Compressors

- Virtually maintenance-free

- No oil changes required

- Fewer consumable parts to replace

Tip: While oil free systems may have a shorter lifespan, the lower maintenance cost can often make up for this over time.

Air Compressor Considerations

When choosing between an oil air compressor and an oil free model, it’s important to think beyond performance and price. Factors like noise levels, lifespan, and environmental impact can play a crucial role depending on where and how your compressor will be used.

Noise

- Oil free compressors are generally louder due to the lack of oil cushioning in the motor and piston mechanism. Always check the decibel rating if your workspace is noise-sensitive.

- Oil lubricated compressors typically run quieter and smoother, making them ideal for environments where reduced noise levels are essential.

Lifespan

- Oil lubricated compressors tend to have a longer operational life—provided they are well-maintained—thanks to reduced internal wear and better cooling.

- Oil free compressors are designed for convenience and cleanliness, but the absence of lubrication means they often wear out faster, especially in high-demand settings.

Environmental Impact

- Oil free compressors are the eco-friendlier option. They eliminate the risk of oil leaks, require no oil disposal, and produce cleaner air—ideal for sustainability-conscious industries.

- Oil lubricated models may require careful handling and proper disposal of used oil, adding to the environmental management requirements.

FAQs

What is better: oil or oil free air compressor?

It depends on your application. Oil air compressors are better for high-intensity or industrial jobs. Oil free air compressors are better for clean environments like healthcare and food industries.

Are oil free air compressors really maintenance free?

While oilless air compressors don’t require oil changes, they still need basic checks like air filter changes and moisture drainage from the tank. So, not entirely maintenance-free, but certainly low-maintenance.

Can I use an oil lubricated air compressor for painting?

Yes, but be cautious. Oil carryover could contaminate the paint finish. Use a high-quality air filtration system or opt for an oil free compressor for cleaner results.

Allow Griffin to Help You Choose the Right Air Compressor

Choosing between an oil free air compressor and an oil lubricated air compressor ultimately depends on your application, maintenance tolerance, budget, and the need for air purity.

Our team at Griffin Air Systems is ready to help you choose the best air compressor for your business. We stock a wide range of compressor systems and can provide expert recommendations tailored to your needs. Contact us today for a free consultation.