Air compressors are a vital component in a wide range of industries—from manufacturing to automotive and construction. However, they’re also notorious for high energy consumption. If you’re relying on compressed air systems in your business, you might be spending far more on energy than you realise.

This blog explores how switching to energy-efficient air compressors can dramatically cut your energy bills, boost operational efficiency, and support your environmental goals. Whether you’re upgrading your current setup or buying new, we’ll guide you through everything you need to know to maximise air compressor energy savings.

- What Are Energy-Efficient Air Compressors?

- Why Energy Efficiency Matters in Compressed Air Systems

- How to Choose an Energy-Efficient Air Compressor

- Key Takeaways for Energy-Efficient Air Compressors

- Energy Efficient Air Compressor FAQs

What Are Energy-Efficient Air Compressors?

Energy efficiency in air compressors refers to how effectively a machine converts electrical energy into compressed air with minimal waste. Traditional systems often operate with fixed-speed motors that run at full capacity, regardless of demand, wasting significant amounts of energy in the process.

Types of Energy-Efficient Air Compressors

Some of the most common energy-efficient air compressors include:

- Variable Speed Drive (VSD) Compressors: Adjust motor speed to match demand, reducing energy waste.

- Two-Stage Compressors: Compress air in two steps, improving efficiency and performance.

- Oil-Free Compressors: Require less maintenance and operate with cleaner, more energy-efficient processes.

Why Energy Efficiency Matters in Compressed Air Systems

Environmental Impact

According to the Carbon Trust, compressed air systems typically waste 20–30% of the energy they consume. That’s a considerable footprint when you consider their usage across industrial applications. Energy-efficient compressors help reduce CO₂ emissions, contributing to broader sustainability goals.

Cost of Inefficiency

Running an inefficient air compressor can account for up to 40% of a facility’s total electricity bill. These costs accumulate over time and eat into your bottom line.

Here’s where energy-efficient models shine:

- Lower operating costs

- Reduced maintenance

- Less downtime

- Extended equipment lifespan

Government Incentives

Many UK-based businesses may qualify for government schemes or tax incentives when upgrading to more energy-efficient systems under initiatives like the Enhanced Capital Allowance (ECA).

How to Choose an Energy-Efficient Air Compressor

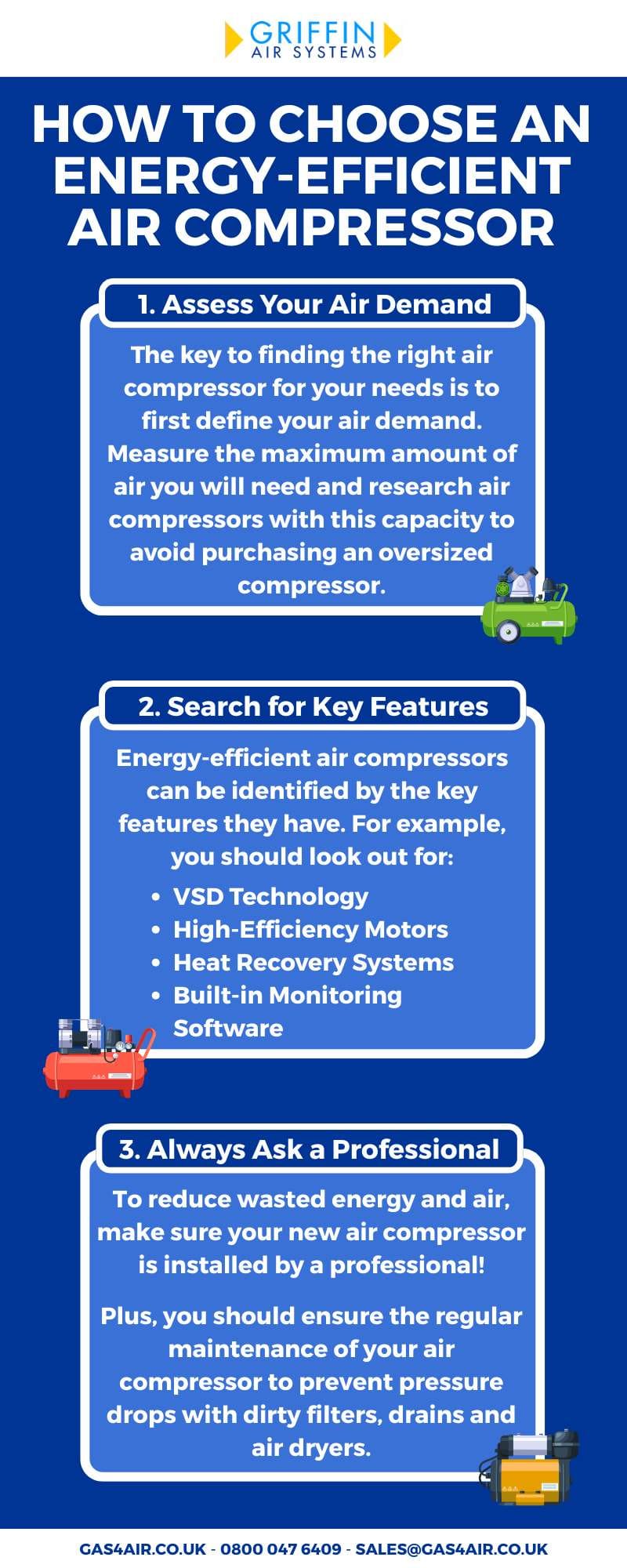

Assess Your Air Demand

A detailed air audit will help identify your actual compressed air needs. This allows you to avoid over-specifying and wasting energy on an oversized compressor.

Key Features to Look For

- VSD Technology – Adjusts motor speed to meet real-time demand.

- High-Efficiency Motors – Uses less electricity for the same output.

- Heat Recovery Systems – Captures and reuses waste heat.

- Built-in Monitoring Software – Helps you track usage and spot inefficiencies.

Installation & Maintenance Considerations

Proper installation plays a major role in energy efficiency. At Griffin, our compressor installation services ensure your equipment is set up for optimal performance.

Don’t forget ongoing maintenance. Regular servicing of filters, drains and air dryers can prevent pressure drops and energy waste. Learn more about our maintenance support.

Key Takeaways for Energy-Efficient Air Compressors

- Energy-efficient air compressors reduce electricity usage and CO₂ emissions.

- VSD and two-stage models offer superior performance and cost savings.

- Energy-efficient models can slash your compressed air energy bill by up to 30%.

- Choosing the right compressor involves assessing your air demand and usage patterns.

- Government incentives may be available to offset the cost of upgrading.

- Regular maintenance is key to long-term energy savings.

Energy Efficient Air Compressor FAQs

What makes an air compressor energy-efficient?

An air compressor is considered energy-efficient when it delivers the required air pressure using the least amount of energy.

This is achieved through innovations such as:

- Variable speed drives (VSD)

- Efficient motor designs

- Reduced air leakage

- Advanced monitoring systems

These features ensure that the machine only uses the energy it needs, which significantly reduces waste.

How much can I save by switching to an energy-efficient model?

Switching to an energy-efficient air compressor can result in energy savings of 20–50%, depending on your current setup and usage habits. The payback period is often just 1–3 years, especially when you factor in reduced maintenance and longer machine life.

Are variable speed compressors more efficient?

Yes. VSD compressors are among the most energy-efficient air compressors available today. Unlike fixed-speed units, which run at a constant rate, VSD units adjust output to match real-time demand. This adaptability prevents unnecessary energy consumption during low-demand periods.

Choose Your Energy Efficient Air Compressor with Griffin Air Systems

Investing in an energy-efficient air compressor is a smart decision for any business aiming to cut costs and reduce its carbon footprint. Whether you’re in manufacturing, construction, automotive, or another sector, upgrading your compressed air system can lead to substantial benefits.

At Griffin Air Systems, we offer a wide range of high-performance, energy-saving compressors with our expert installation, and full maintenance support. Explore our air compressor range or contact us for a free consultation.

Take the first step towards air compressor energy savings today with Griffin Air Systems.