When it comes to compressed air systems, many UK businesses focus on the compressor itself but overlook one of the most critical factors – the air compressor pipework. A poorly designed or incorrectly installed compressed air piping system can lead to pressure drops, costly leaks, wasted energy, and reduced tool efficiency.

At Griffin Air Systems, we’ve spent years helping companies design, install, and maintain efficient air compressor pipes and fittings across the UK. This guide will walk you through the best practices for air compressor installation, with a particular focus on pipework design and leak prevention.

By the end, you’ll know exactly how to reduce wasted energy, improve system performance, and save money through professional air leakage detection and proper installation methods.

- Why Proper Air Compressor Pipework Installation Matters

- Choosing the Right Pipe for Compressed Air Systems

- Best Practices for Designing Air Compressor Pipework Layout

- Common Mistakes to Avoid in Air Compressor Installation

- Air Pipe Fittings: Selecting and Installing the Right Components

- How to Detect and Prevent Air Compressor Leaks

- Best Practices for Long-Term Efficiency in Compressed Air Piping Systems

- Why Partner with Griffin Air Systems for Pipework Installation

- Key Takeaways for Air Compressor Pipework

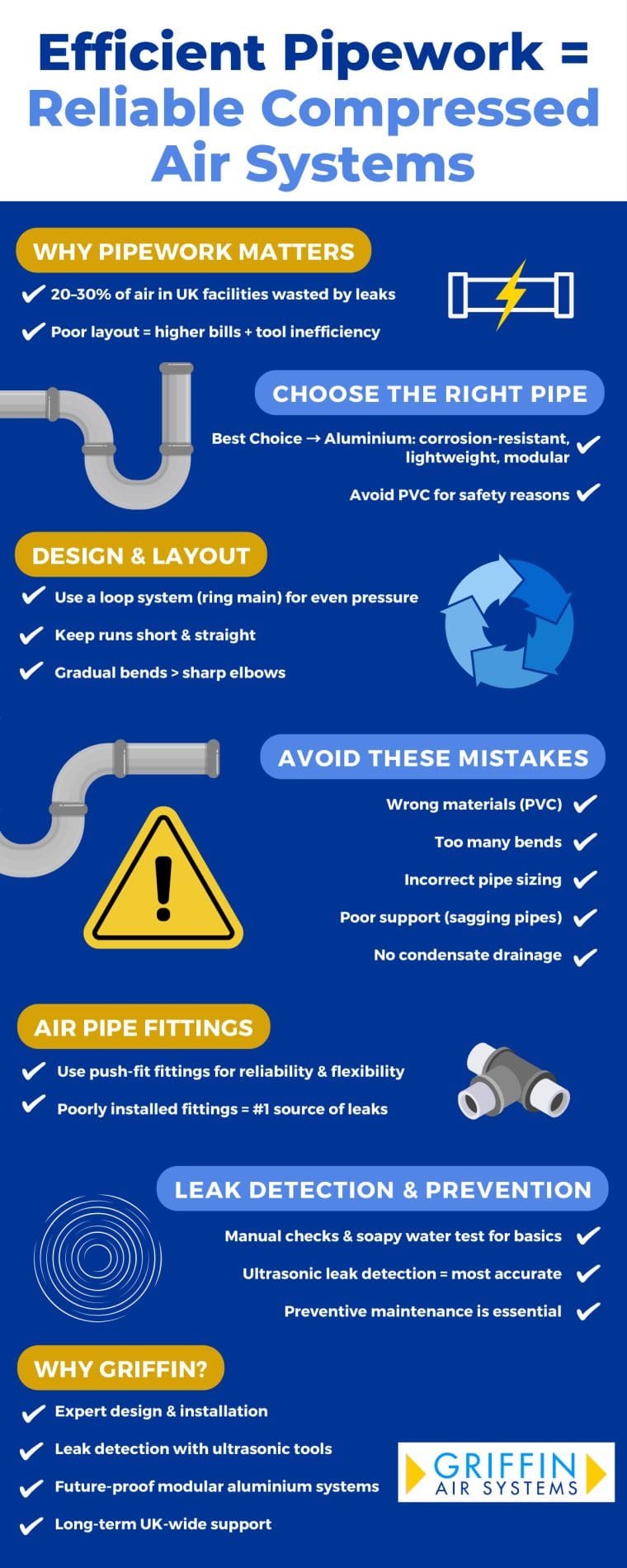

Why Proper Air Compressor Pipework Installation Matters

The pipework in a compressed air system is far more than a series of tubes connecting equipment. It’s the circulatory system that ensures compressed air reaches every tool, machine, and application point with minimal loss of pressure or energy.

If your compressed air pipes are undersized, poorly routed, or leaking, the entire system has to work harder to maintain pressure. This drives up energy bills, increases wear and tear on the compressor, and reduces the performance of pneumatic tools and machinery.

In fact, industry research shows that 20–30% of compressed air generated in UK facilities is wasted due to leaks. That translates into significant operating costs, unnecessary CO₂ emissions, and lower productivity. For manufacturers, workshops, and industrial facilities, getting pipework installation right from the start is one of the smartest investments you can make.

Choosing the Right Pipe for Compressed Air Systems

The type of pipe for compressed air you select will determine the efficiency, durability, and safety of your system. Not all materials are suitable, and the wrong choice can lead to leaks, corrosion, or even catastrophic failures.

| Pipe Material | Pros | Cons | Best Use Cases |

| Black Iron/Steel | Strong, widely available, handles high pressure | Prone to rust and corrosion, heavy, labour-intensive installation | Legacy systems, high-pressure applications |

| Galvanised Steel | Rust-resistant surface, durable | Risk of flaking zinc coating causing blockages, costly to maintain | Rarely recommended today |

| Copper | Corrosion-resistant, smooth internal surface, long-lasting | Expensive, labour-intensive installation | Clean environments, food & beverage industry |

| Aluminium | Lightweight, corrosion-resistant, easy to install with push-fit fittings | Higher upfront cost | Modern facilities, flexible layouts |

| Plastic (PVC, ABS, PEX) | Low cost, lightweight, easy to install | Not always pressure-rated, risk of cracking, not always legal for compressed air | Temporary or low-pressure systems |

At Griffin Air Systems, we generally recommend aluminium compressed air pipework for UK businesses. It offers:

- Low pressure drop thanks to smooth bore design.

- Long lifespan without rust or corrosion.

- Fast installation with modular, push-fit air pipe fittings.

- Flexibility for system expansions or layout changes.

While upfront costs may be higher, the energy savings and reliability often deliver a rapid return on investment.

Best Practices for Designing Air Compressor Pipework Layout

Even the best pipe material won’t perform well if the layout is inefficient. Poor design leads to turbulence, restrictions, and uneven air pressure across your facility.

Use a Loop System

A ring main or loop layout ensures even pressure across the facility by allowing compressed air to flow in multiple directions. This prevents “starving” tools at the farthest points.

Minimise Pressure Drop

- Keep pipe runs as short and straight as possible.

- Use gradual bends instead of sharp 90-degree elbows.

- Size pipes correctly – undersized lines cause excessive friction and wasted energy.

Plan for Expansion

Many businesses grow, add machinery, or change their floor layout. By using modular aluminium piping systems supplied by Griffin, you can easily extend or modify your network without costly downtime.

Common Mistakes to Avoid in Air Compressor Installation

Even small errors during installation can lead to significant inefficiencies later. Here are the most common mistakes we see in UK facilities:

- Using the wrong pipe material – PVC pipes are dangerous under pressure and should never be used for compressed air.

- Too many sharp bends – Each bend increases turbulence and pressure loss.

- Incorrect pipe sizing – Oversized pipes are costly, while undersized pipes cause bottlenecks.

- Poor support and alignment – Sagging pipes lead to water pooling and corrosion.

- Neglecting condensate management – Without proper drainage, moisture damages equipment and reduces air quality.

Working with Griffin Air Systems ensures your compressed air piping system is professionally designed, installed, and tested, so you avoid these costly mistakes.

Air Pipe Fittings: Selecting and Installing the Right Components

Choosing the right air pipe fittings is just as important as selecting the pipe itself. Fittings are often the source of air compressor leaks, so quality and correct installation are key.

Types of Air Pipe Fittings

- Threaded fittings – Traditional, but prone to leaks if overtightened or improperly sealed.

- Compression fittings – Create a strong seal without welding, suitable for medium-duty applications.

- Push-to-connect fittings – Easy to install, reusable, and highly reliable for modern compressed air piping systems.

Griffin’s Approach to Fittings

Our team at Griffin only uses industry-approved, high-performance air pipe fittings that minimise leakage risk. We also ensure correct torque and alignment during installation, as improper tightening is one of the leading causes of leaks.

How to Detect and Prevent Air Compressor Leaks

Finding leaks in compressed air systems is challenging, especially in noisy industrial environments. However, ignoring them can waste thousands of pounds annually.

Visual and Manual Inspections

Regularly walk through your facility and listen for hissing sounds, check for worn hoses, or feel for escaping air at joints. While basic, this method is a good first step.

Soapy Water Test

Applying a soapy solution to suspected leak points will produce bubbles where leaks exist. This is effective for small systems but impractical for larger networks.

Ultrasonic Leak Detector Technology

The most effective solution is using an ultrasonic leak detector. These devices detect the high-frequency sound waves produced by escaping air.

Best Practices for Long-Term Efficiency in Compressed Air Piping Systems

If you want to stop leaks for good, a one-off fix won’t be enough. Instead, adopt long-term best practices to maintain system performance.

Preventive Maintenance: Schedule regular service checks to keep your air compressor pipework in top condition. Griffin offers tailored maintenance packages across the UK.

Data Monitoring: Use flow meters and monitoring tools to track usage and quickly identify abnormal air loss.

Upgrade Proactively: Replace outdated steel pipes with modern aluminium systems for improved reliability and efficiency.

Employee Training: Equip staff to spot leaks early and understand the cost implications.

Work with Experts: Partnering with Griffin ensures you benefit from decades of experience, proven leak detection methods, and a complete system approach.

Why Partner with Griffin Air Systems for Pipework Installation

Choosing the right partner for your air compressor installation and pipework design is critical. At Griffin Air Systems, we don’t just fit pipes – we deliver complete compressed air piping systems that are efficient, reliable, and built for the future.

Here’s what makes us different:

- Expertise you can trust – Our engineers have decades of experience in compressed air systems across UK industries.

- End-to-end service – From design and installation to ongoing air leakage detection and maintenance, we manage everything.

- Energy savings focus – We prioritise low-leakage air pipe fittings and efficient layouts to reduce your energy bills.

- Future-ready systems – Our modular aluminium air compressor pipework makes it simple to adapt as your business grows.

- Proven results – Businesses across the UK partner with Griffin to cut costs, improve efficiency, and meet sustainability goals.

When you work with Griffin, you gain a long-term partner who ensures your compressed air system performs at its best.

Key Takeaways for Air Compressor Pipework

- Poor pipework can waste 20–30% of compressed air in UK facilities.

- Choosing the right air compressor pipes and fittings is crucial for efficiency and safety.

- The best layout is a loop system with minimal bends and correct pipe sizing.

- Regular inspections, leak detection, and staff training prevent costly air losses.

- Ultrasonic leak detectors are the most effective way to identify hidden leaks.

- Griffin Air Systems provides UK-wide design, installation, upgrades, and leak detection services.

- Partnering with experts like Griffin helps businesses cut costs, extend compressor lifespan, and reduce carbon emissions.

FAQs

What type of pipe is best for compressed air installation?

The best pipe for compressed air systems in the UK is typically aluminium piping. It’s lightweight, corrosion-resistant, easy to install, and reduces pressure drops compared to traditional steel. Griffin Air Systems supplies and installs high-quality aluminium and stainless steel systems tailored to your needs.

How do I design an efficient compressed air piping system?

To design an efficient compressed air piping system, use a loop layout, size pipes correctly, and minimise sharp bends. Include air pipe fittings that are leak-resistant and install condensate drains to manage moisture. Partnering with Griffin ensures your installation is professionally designed for maximum reliability and efficiency.

Can Griffin Air Systems help with air compressor pipework in the UK?

Yes. Griffin Air Systems provides complete air compressor installation and pipework solutions across the UK. Our services include design, supply, installation, leak detection with ultrasonic technology, and long-term maintenance programmes to ensure your system stays efficient and cost-effective.

Optimise Your Air Compressor Pipework with Griffin Air Systems

Efficient compressed air piping systems are the backbone of reliable industrial operations. By choosing the right air compressor pipes and fittings, avoiding common mistakes, and adopting proactive maintenance, UK businesses can significantly reduce energy waste and boost productivity.

At Griffin Air Systems, we specialise in designing and installing leak-free, energy-efficient air compressor pipework that grows with your business. Our expert engineers use advanced air leakage detection tools, including ultrasonic leak detectors, to identify and eliminate costly leaks.

If you’re looking to improve your system performance, lower energy bills, and future-proof your compressed air installation, our team is here to help – contact us today!

Related Articles

- 10 Common Compressed Air Leaks (And How to Fix Them)

- Troubleshooting Common Air Compressor Problems

- Air Compressor Maintenance 101: Keeping Your Machine Running Smoothly