Discover how energy air compressors support your sustainability goals. Ideal for eco-conscious industries, explore our new or used air compressors at Griffin.

Sustainability has become a central priority for businesses across the UK. Whether you’re working in manufacturing, food production, pharmaceuticals, or engineering. Reducing carbon emissions, improving energy efficiency, and meeting environmental targets are essential steps in securing your company’s future.

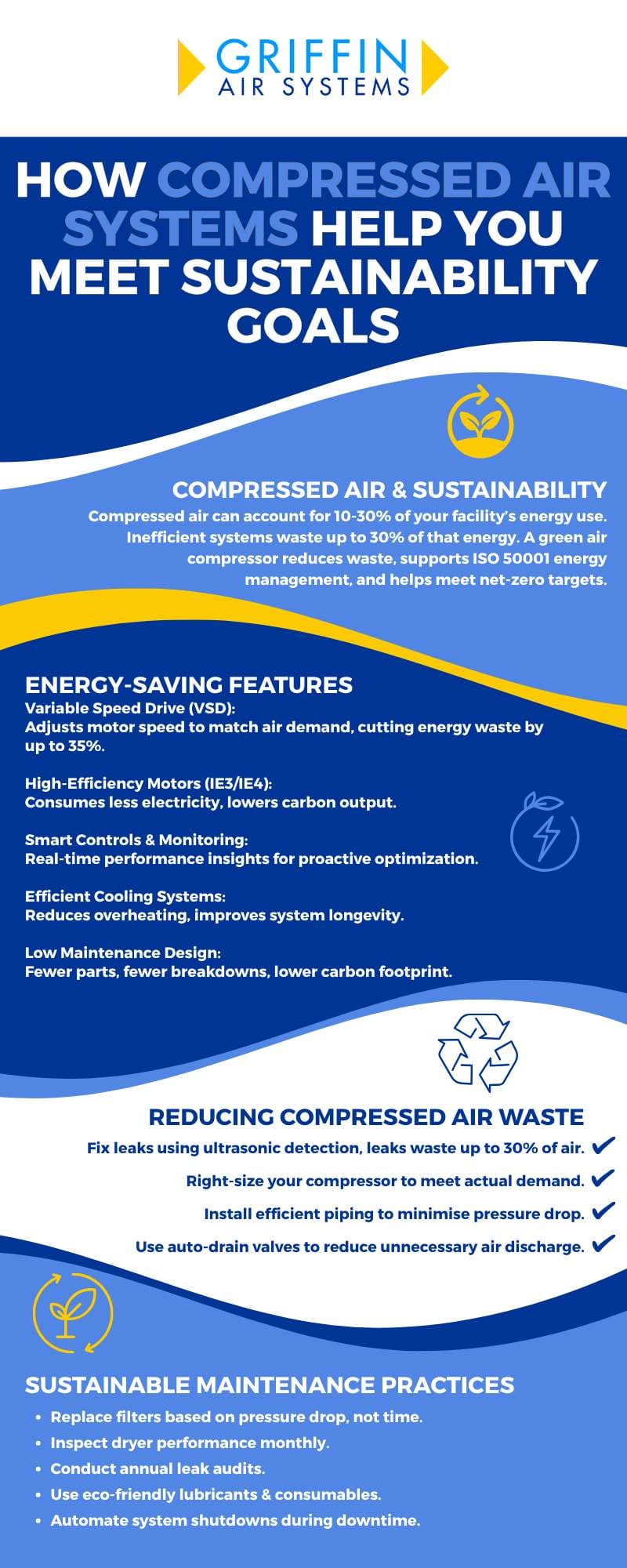

One often-overlooked opportunity to improve sustainability is through your compressed air system. From choosing the most energy efficient air compressor to upgrading old infrastructure with a green air compressor, the right system can help reduce energy waste, cut operational costs, and align your operations with net-zero goals.

At Griffin Air Systems, we help clients across Scotland and the UK identify and implement efficient compressor solutions that reduce emissions and support long-term sustainability.

- How Compressed Air Systems Impact Sustainability

- The Link Between Air Compressors and Energy Consumption

- Features of the Most Energy Efficient Air Compressors

- Reducing Waste with Modern Compressed Air Technology

- Sustainable Maintenance Practices for Air Compressors

- Upgrading to a Green Air Compressor: What to Consider

How Compressed Air Systems Impact Sustainability

Compressed air is considered the fourth utility in many industries, alongside electricity, water, and gas. However, it is also one of the most inefficient if not properly maintained or specified. Poorly managed systems can result in up to 30% energy waste, a significant figure when sustainability is on the line.

Hidden Costs of Inefficient Systems

- Excess electricity usage

- Increased carbon emissions

- Downtime and system inefficiencies

- Greater wear and tear on components

A green air compressor system not only saves energy but also supports ISO 50001 energy management standards, helps businesses meet ESG goals, and demonstrates a clear commitment to sustainability.

The Link Between Air Compressors and Energy Consumption

Compressed air systems can account for 10-30% of a facility’s energy use, particularly in energy-intensive sectors like manufacturing and fabrication.

How Energy Air Compressors Help:

- Reduce kWh consumption per production output

- Optimise pressure settings to prevent overuse

- Use Variable Speed Drive (VSD) technology to match demand

- Recover heat for use elsewhere in the facility

Features of the Most Energy Efficient Air Compressors

Investing in an efficient air compressor is one of the fastest ways to lower operational carbon output without sacrificing productivity.

If you’re looking to improve sustainability, choosing the most energy efficient air compressor is essential.

Here’s what to look for:

1. Variable Speed Drive (VSD) Technology

VSD compressors automatically adjust motor speed to match your air demand, reducing energy waste by up to 35%. By eliminating the constant start-stop cycle of traditional compressors, VSD technology ensures smoother operation, extends equipment lifespan, and significantly lowers electricity costs.

2. High-Efficiency Motors

Motors with IE3 or IE4 ratings consume less electricity and perform better under high demand. These energy-efficient motors are designed to deliver consistent output with minimal loss, making them ideal for businesses aiming to lower carbon emissions and improve overall system performance.

3. Smart Controls & Monitoring

Integrated monitoring systems track performance and suggest improvements in real-time. These smart controls provide valuable insights into energy usage, pressure levels, and maintenance schedules, helping you optimise operations proactively.

4. Efficient Cooling Systems

Modern compressors use advanced thermal management systems to reduce overheating and prevent unnecessary shutdowns. Efficient cooling not only boosts performance and longevity but also cuts down on the energy required to regulate internal temperatures.

5. Low Maintenance Design

The fewer moving parts, the less energy wasted and the fewer emissions generated from maintenance logistics. Simplified system architecture means fewer breakdowns, less downtime, and a smaller carbon footprint associated with repairs and part replacements.

Reducing Waste with Modern Compressed Air Technology

Beyond choosing the right compressor, air system design plays a crucial role in energy savings.

4 Ways to Reduce Compressed Air Waste:

- Identify and fix leaks using ultrasonic leak detection services: Leaks can account for up to 30% of compressed air waste, so regular inspections are essential. Fixing leaks not only cuts energy bills but also improves system reliability and performance.

- Right-size your compressor for current production demands: Oversized systems run inefficiently and waste energy during low-demand periods. A correctly sized compressor ensures optimal output without excess energy consumption.

- Install efficient piping with minimal pressure drop: Poor piping layouts can lead to significant energy losses as air pressure decreases. Streamlined piping design keeps pressure consistent and reduces the workload on the compressor.

- Implement auto-drain valves to reduce unnecessary discharge: Manual draining often results in compressed air loss and inefficiencies. Automatic valves only release condensate when needed, preserving air and improving sustainability.

Even small upgrades can deliver significant energy savings, helping your business move toward greener operations.

Sustainable Maintenance Practices for Air Compressors

Sustainability doesn’t stop at installation. Routine servicing and smart usage habits can extend the life of your system while supporting eco goals.

Maintenance Tips for a Green Air Compressor System:

- Schedule regular servicing to prevent build-up and inefficiency: Dust, oil, and debris can accumulate in the system, causing strain and energy loss. Planned maintenance ensures all components operate at peak efficiency for longer.

- Replace filters and seals to maintain clean airflow: Clogged filters force compressors to work harder, increasing energy consumption. Fresh filters and intact seals support optimal air quality and lower system resistance.

- Use energy-efficient lubricants and consumables: The right lubricants reduce friction and improve mechanical performance. Eco-friendly consumables can also extend the life of your system and reduce waste.

- Conduct annual leak audits: Leaks are a hidden but costly source of energy inefficiency in most systems. A yearly audit can uncover and address leaks before they inflate your energy costs.

- Implement automated system shutdowns during downtime: Idle compressors still draw power if left running unnecessarily. Automated controls ensure systems power down when not in use, cutting emissions and cost.

Upgrading to a Green Air Compressor: What to Consider

If your current compressor system is outdated, now may be the perfect time to upgrade. Switching to a green air compressor can significantly cut your energy bill and reduce your carbon footprint.

Key Questions Before Upgrading:

- Is your current system oversized or undersized?

- Have you experienced frequent pressure drops?

- Are your energy bills steadily increasing?

- Do you need to meet compliance standards like ISO 14001 or SECR?

Griffin Air Systems can assess your site, calculate air demand, and recommend the most energy efficient air compressor options for your business.

Key Takeaways for Energy Air Compressor Solutions

- Compressed air systems can be major energy consumers, but also offer huge sustainability potential.

- Investing in the most energy efficient air compressor reduces energy waste and carbon emissions.

- Features like VSD, smart controls, and leak detection contribute to greener operations.

- Regular maintenance is essential for maintaining system performance and sustainability.

- Griffin Air Systems provides tailored solutions that help your business meet its environmental and cost-saving goals.

FAQs

What is the most energy efficient air compressor?

The most energy efficient air compressor is typically one that uses Variable Speed Drive (VSD) technology, a high-efficiency motor (IE3/IE4), and smart monitoring systems. Scroll compressors and oil-free rotary screw compressors are also highly efficient for certain applications.

How does a green air compressor differ from a traditional system?

A green air compressor is designed for low environmental impact – featuring energy-saving components, low emissions, and efficient heat recovery. It typically uses fewer natural resources over its lifespan and supports sustainable business goals.

Can upgrading my air compressor system help us meet our sustainability targets?

Yes! Upgrading to an energy air compressor can help reduce electricity consumption, carbon output, and maintenance costs – all of which contribute to corporate ESG reporting and ISO 14001 environmental management goals.

Improve Your Sustainable Energy Performance with Griffin Air Systems

If your business is serious about reducing emissions, improving energy performance, and lowering operational costs, your compressed air system is a great place to start.

At Griffin Air Systems, we specialise in specifying and supplying the most energy efficient air compressors for businesses across Scotland and the UK. Whether you’re upgrading your current setup or starting from scratch, we’ll help you find the green air compressor system that aligns with your goals. Contact us today to learn more about how we can help.