Explore how to choose the best air compressor dryer for your needs. Improve efficiency, protect equipment, and reduce moisture. Get expert advice from Griffin.

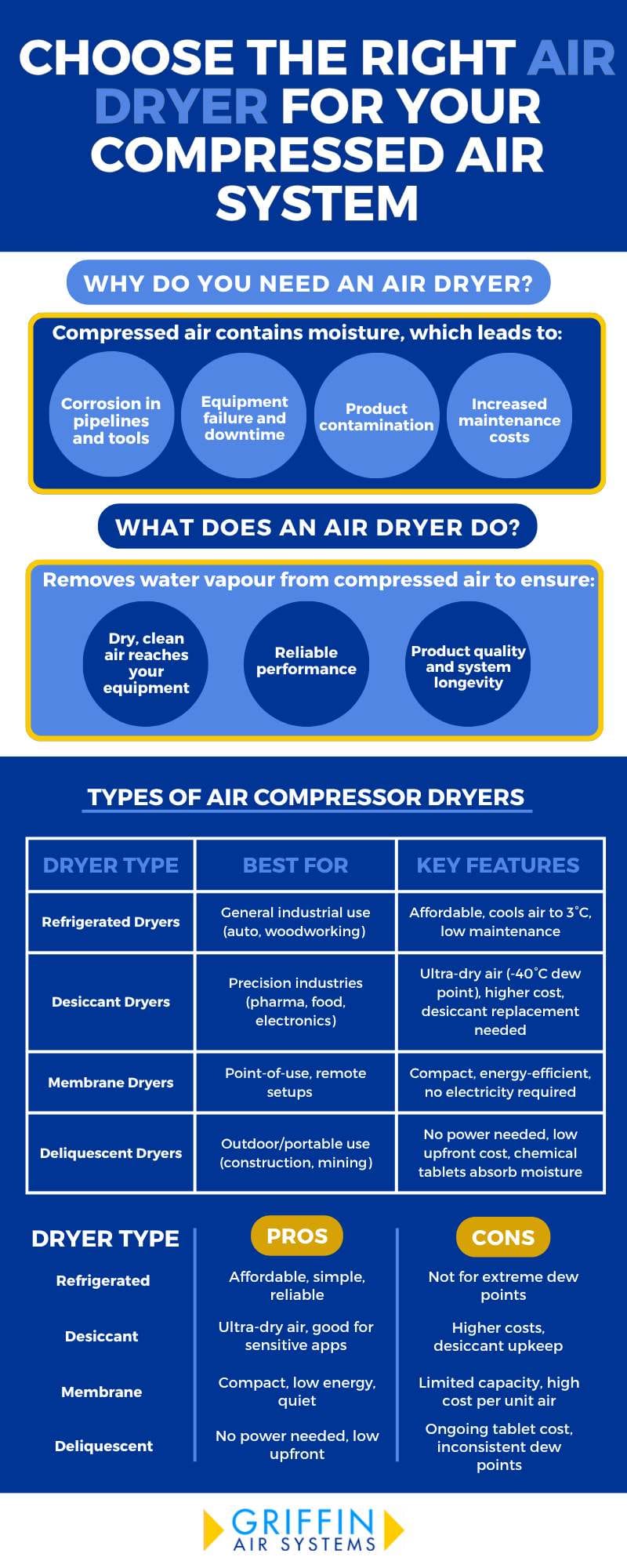

If you’re investing in an air compressor system, choosing the right air compressor dryer is just as important as selecting the compressor itself. Without proper air drying, moisture can build up in your system – leading to corrosion, equipment failure, reduced product quality, and expensive downtime.

This guide walks you through everything you need to know about air drying solutions, the different types of air dryer systems for air compressors, and how to match the right one with your operational needs. Whether you run a small workshop or a large-scale production facility, we’ll help you identify the best-fit industrial air dryer for your compressed air dryer system.

- What Does an Air Compressor Dryer Do?

- Why Moisture Is a Problem in Compressed Air Systems

- Key Types of Air Compressor Dryers

- Pros and Cons of Each Air Compressor Dryer

- Choosing the Right Dryer for Your Application

- Key Takeaways for Air Dryer Compressed Air Systems

What Does an Air Compressor Dryer Do?

An air compressor dryer removes moisture (water vapour) from compressed air before it reaches your tools, equipment, or end products. While air is compressed, water vapour is concentrated, increasing the likelihood of:

- Corrosion in pipelines and air tools

- Malfunctioning pneumatic equipment

- Contaminated or ruined products

- Increased maintenance costs and unscheduled downtime

An air dryer system for air compressors is crucial for protecting equipment, improving efficiency, and ensuring consistent output across all industries.

Why Moisture Is a Problem in Compressed Air Systems

Moisture causes serious complications in industrial and commercial settings:

Corrosion: Metal piping and machinery degrade over time with continuous exposure to water.

Bacterial Growth: In food-grade and pharmaceutical applications, water creates an ideal environment for bacteria.

Product Defects: Moisture can affect the consistency, finish, or integrity of your end products.

Reduced Lifespan of Equipment: Tools and valves wear out faster when exposed to water-laden air.

By removing this moisture through a well-chosen compressed air dryer system, you can ensure reliable and efficient performance across your operation.

Key Types of Air Compressor Dryers

There are several types of air dryers, each suited to different conditions, budgets, and industries.

1. Refrigerated Air Dryers

Best for: General industrial applications where dew point requirements aren’t extreme, such as automotive, woodworking, and manufacturing.

How it works: These dryers cool compressed air to around 3°C (37°F), causing moisture to condense and separate from the air before reheating it to prevent pipe condensation.

2. Desiccant Air Dryers

Best for: Critical applications requiring ultra-dry air, including pharmaceuticals, food processing, and electronics manufacturing.

How it works: These dryers use desiccant materials like activated alumina to adsorb moisture from compressed air, delivering dew points as low as -40°C or lower.

3. Membrane Air Dryers

Best for: Point-of-use applications and remote areas where compactness and reliability are key, such as labs and small workshops.

How it works: Compressed air passes through a membrane that selectively allows water vapour to diffuse through, leaving dry air behind.

4. Deliquescent Air Dryers

Best for: Portable or outdoor use where electricity is unavailable, often in mining or construction environments.

How it works: Moisture is removed as compressed air interacts with a chemical tablet (deliquescent agent) that gradually dissolves as it absorbs water.

Pros and Cons of Each Air Compressor Dryer

| Dryer Type | Pros | Cons |

| Refrigerated | Affordable and easy to install

Low maintenance Reliable for moderate humidity control |

Not suitable for sub-zero dew points

Less efficient in high-humidity environments |

| Desiccant | Ideal for sensitive systems

Delivers very low dew point air Works well in cold climates |

Higher initial and running costs

Desiccant needs regular replacement or regeneration |

| Membrane | Quiet and compact

Energy-efficient No electricity required Minimal maintenance |

Limited capacity

Not ideal for high-volume use Higher cost per unit of dried air |

| Deliquescent | No moving parts

Works without power Good for remote locations Low upfront cost |

Ongoing cost for deliquescent agent

Inconsistent dew points Not suited for precision applications |

Choosing the Right Dryer for Your Application

Selecting the right air dryer isn’t just about picking the most expensive or powerful unit – it’s about finding the best fit for your specific setup and operational goals. Here’s what you need to weigh up before making a decision:

1. Required Dew Point

For general use, such as powering air tools or running a workshop, a dew point of around 3°C is typically more than enough to protect your equipment from moisture.

For high-precision industries like pharmaceuticals, food production, or electronics, you’ll need a much lower dew point (typically -40°C or below) to meet regulatory standards and protect delicate components.

2. Air Flow Requirements

Your dryer’s capacity, measured in cubic feet per minute (CFM), must match your air compressor’s output.

If it’s too small, the system becomes overworked and less effective. If it’s too large, you may end up wasting energy and money. Always check your system’s airflow needs before committing to a model.

3. Operating Environment

In cold or outdoor environments, choose a dryer that’s designed to prevent freezing or moisture buildup, especially in piping.

In warmer or poorly ventilated areas, look for units with enhanced cooling systems to keep performance consistent and avoid overheating.

4. Energy Efficiency

Modern dryers come with features like energy-saving modes, load-sensing controls, and Variable Speed Drives (VSDs) to help reduce your power consumption without sacrificing performance. Over time, these features can lead to substantial cost savings.

5. Maintenance Needs

Some dryers are low-maintenance and easy to manage, while others require more hands-on attention and regular part replacements. Choose a dryer that matches the capabilities of your in-house team or external service providers.

6. Budget

While cheaper dryers can save you upfront, they may cost more in the long run due to higher energy use, more frequent maintenance, or limited lifespan. Always factor in the total cost of ownership, including installation, running costs, and servicing needs.

Key Takeaways for Air Dryer Compressed Air Systems

- An air dryer compressed air system is critical for removing moisture and avoiding costly damage.

- Refrigerated dryers are perfect for general industrial air use.

- Desiccant dryers suit precision industries with ultra-dry air requirements.

- Membrane and deliquescent dryers are ideal for portable or point-of-use setups.

- Always match your dryer to your compressor size, environment, and required dew point.

- A well-selected dryer enhances system longevity, energy efficiency, and product quality.

FAQs

What is the purpose of an air compressor dryer?

An air compressor dryer removes water vapour from compressed air, preventing corrosion, equipment failure, and product defects.

How do I choose the right air dryer for my compressor?

Match the dryer to your system’s CFM, dew point needs, environmental conditions, and industry-specific requirements. Consult a supplier like Griffin Air Systems for tailored advice.

Do I need a dryer for my air compressor?

Yes, moisture in compressed air can severely damage equipment, tools, and products. Even basic applications benefit from having a reliable air dryer in place.

Can I hire an air compressor dryer?

Absolutely! At Griffin, we offer an affordable hire service for all of our air dryers. Simply contact our expert team today and we can customise a hire plan to suit your business needs.

Find the Right Dryer for Your Compressed Air System

Choosing the right air dryer system for air compressors is key to protecting your equipment, reducing operating costs, and ensuring consistent production quality. From refrigerated to desiccant options, there’s a solution for every industry and budget.

At Griffin Air Systems, we can help you size and source the right industrial air dryer for your operations, we offer air dryer hire for both short and long term hire. Contact our team for expert support and browse our full range of air compressors.