Clean, dry compressed air is vital in a wide range of industries—from food and beverage production to pharmaceuticals, automotive manufacturing, and electronics. But how do you define “clean” when it comes to compressed air? That’s where ISO 8573 comes in.

The ISO 8573 air quality standards provide a global benchmark for measuring contaminants in compressed air systems. Understanding these standards is critical if you want to ensure compliance, protect your equipment, maintain product quality, and safeguard workplace health. This guide will help you understand what these air quality standards mean, how they’re measured, and why they matter.

- What is ISO 8573?

- Why Air Quality Standards Matter in Compressed Air Systems

- Breaking Down ISO 8573: The 3 Types of Contaminants

- Understanding the ISO 8573-1 Classification System

- How to Ensure Compliance with ISO 8573

What Is ISO 8573?

ISO 8573 is an international standard developed by the International Organisation for Standardisation (ISO) to define acceptable levels of purity in compressed air. It consists of multiple parts, but the most referenced is ISO 8573-1, which categorises contaminants and classifies acceptable limits.

This standard provides a universally recognised way to define measures of air quality, so that businesses can specify, verify, and maintain the purity of their compressed air systems.

Why Air Quality Standards Matter in Compressed Air Systems

Compressed air is often considered the “fourth utility” in many industries. If it’s contaminated with oil, water vapour, or particles, it can compromise:

- Product quality (e.g., food contamination, coating defects)

- Operational reliability (e.g., valve clogging, sensor malfunction)

- Employee health and safety (e.g., respiratory risks)

- Equipment lifespan and performance

In the UK workplace, compliance with air quality standards not only ensures operational efficiency but also helps companies meet health and safety regulations.

Breaking Down ISO 8573: The 3 Types of Contaminants

ISO 8573 focuses on three major types of contaminants found in compressed air systems:

1. Solid Particulates

These include dust, rust, and metal particles that enter the system through intake air or internal corrosion. Left unchecked, they can damage sensitive equipment and affect product integrity.

2. Water (Vapour and Liquid)

Moisture can cause rust in pipelines and promote bacterial growth. It also leads to freezing in outdoor environments and compromises pneumatic equipment.

3. Oil (Mist, Vapour, and Aerosol)

Oil contamination is particularly dangerous in industries like pharmaceuticals or food processing. It comes from lubricated compressors or ambient air.

Each of these categories has its own purity levels defined under ISO 8573-1.

Understanding the ISO 8573-1 Classification System

ISO 8573-1 is the most referenced part of the standard, and it outlines classes for each contaminant based on their concentration in the air.

ISO 8573-1 Classification Chart

| Class | Solids (μm) | Water (g/m³) | Oil (mg/m³) |

| 0 | As specified by user | As specified by user | As specified by user |

| 1 | ≤ 0.1 | ≤ 0.003 | ≤ 0.01 |

| 2 | ≤ 1.0 | ≤ 0.11 | ≤ 0.1 |

| 3 | ≤ 5.0 | ≤ 0.88 | ≤ 1 |

| 4 | ≤ 15 | ≤ 6.0 | ≤ 5 |

| 5 | ≤ 40 | — | — |

| 6 | — | — | ≤ 5 |

What This Means in Practice

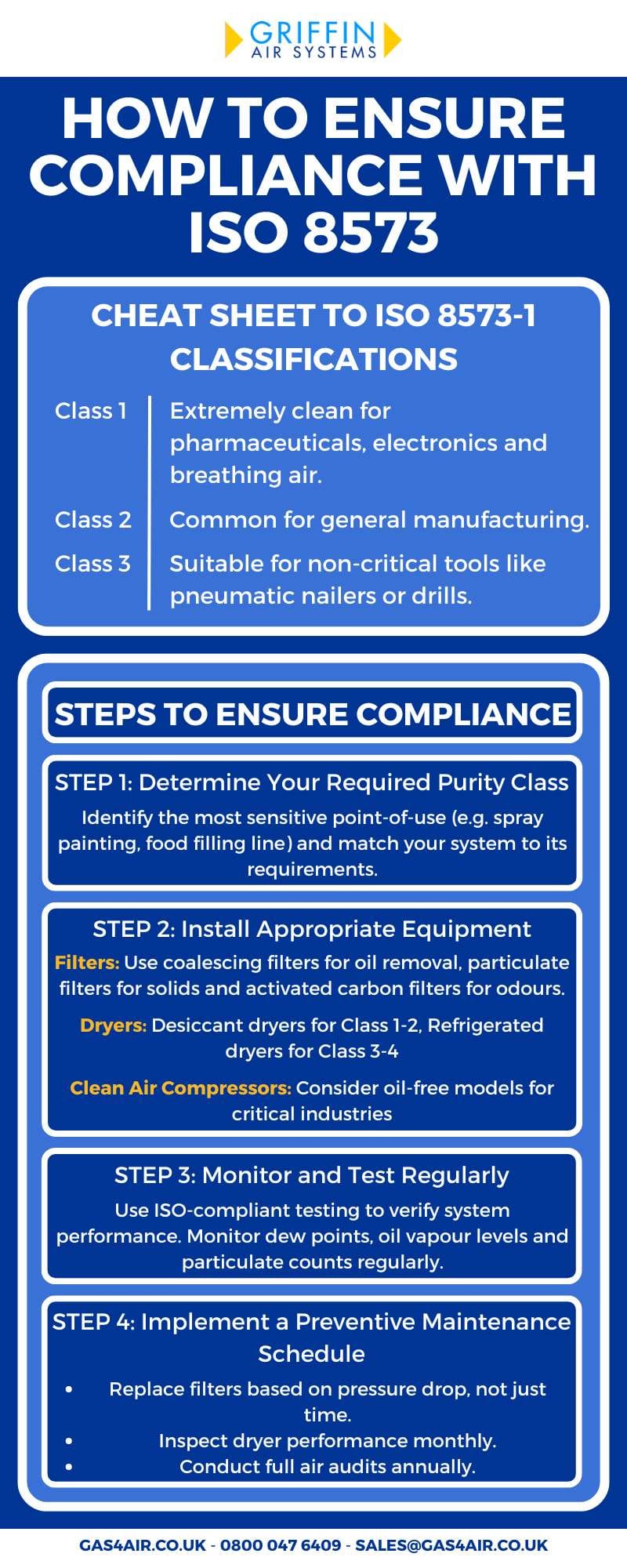

- Class 1 is extremely clean and suitable for applications like pharmaceuticals, electronics, and breathing air.

- Class 3–4 is common in general manufacturing.

- Class 5–6 is suitable for non-critical tools such as pneumatic nailers or drills.

By understanding your specific requirements, you can design a system that maintains the correct air quality standards.

How to Ensure Compliance with ISO 8573

Compliance isn’t just about choosing a clean air compressor—it’s about designing and maintaining a full system that controls contamination at every stage.

Step 1: Determine Your Required Purity Class

Identify the most sensitive point-of-use (e.g. spray painting, food filling line) and match your system to its requirements.

Step 2: Install Appropriate Equipment

- Filters: Use coalescing filters for oil removal, particulate filters for solids, and activated carbon filters for odours.

- Dryers: Desiccant dryers for Class 1-2, refrigerated dryers for Class 3-4.

- Clean Air Compressors: Consider oil-free models for critical industries.

Step 3: Monitor & Test Regularly

Use ISO-compliant testing to verify system performance. Monitor dew points, oil vapour levels, and particulate counts regularly.

Step 4: Implement a Preventive Maintenance Schedule

- Replace filters based on pressure drop, not just time.

- Inspect dryer performance monthly.

- Conduct full air audits annually.

FAQs

What is ISO 8573 in compressed air?

ISO 8573 is a set of international standards that define acceptable levels of contaminants—particles, water, and oil—in compressed air. The most used part, ISO 8573-1, classifies air purity into specific classes depending on the concentration of each contaminant.

How do I meet air quality standards in the workplace UK?

To meet air quality in the workplace UK requirements, use equipment that matches ISO standards, conduct regular testing, and ensure filters and dryers are properly maintained. Employers must ensure the air supply is clean and safe, especially if used for breathing air or in sensitive processes.

What is the cleanest class of air under ISO 8573?

Class 1 is the cleanest commonly used class, with the lowest acceptable levels of particles, moisture, and oil. Class 0 is technically cleaner but must be defined specifically by the user and tested against custom requirements.

Prioritise Clean Air Standards with Griffin Air Systems

Understanding and complying with ISO 8573 compressed air standards is essential for any business that relies on compressed air to maintain product quality, meet regulatory requirements, and ensure operational safety.

We provide full air quality assessments, equipment recommendations, and ongoing maintenance to keep your system clean, efficient, and compliant. Get in touch with our team to learn more about how we can help.