Air Compressor Maintenance | Air Compressor Service | Griffin Air Systems

Discover the top signs your air compressor needs servicing. Avoid breakdowns with preventative maintenance. Book your service with Griffin Air Systems today.

Your air compressor is a workhorse. Whether you’re in manufacturing, automotive repair, or construction, your operations depend on it running smoothly. However, like any piece of machinery, it needs regular attention to perform at its best.

Ignoring small issues can lead to expensive breakdowns and prolonged downtime. Recognising the early signs of trouble can save you time, money, and stress. This blog outlines the key indicators that your compressor needs maintenance—before it fails completely.

At Griffin Air Systems, we provide expert air compressor maintenance, servicing compressors, and preventive maintenance schedules tailored to businesses throughout Scotland and beyond.

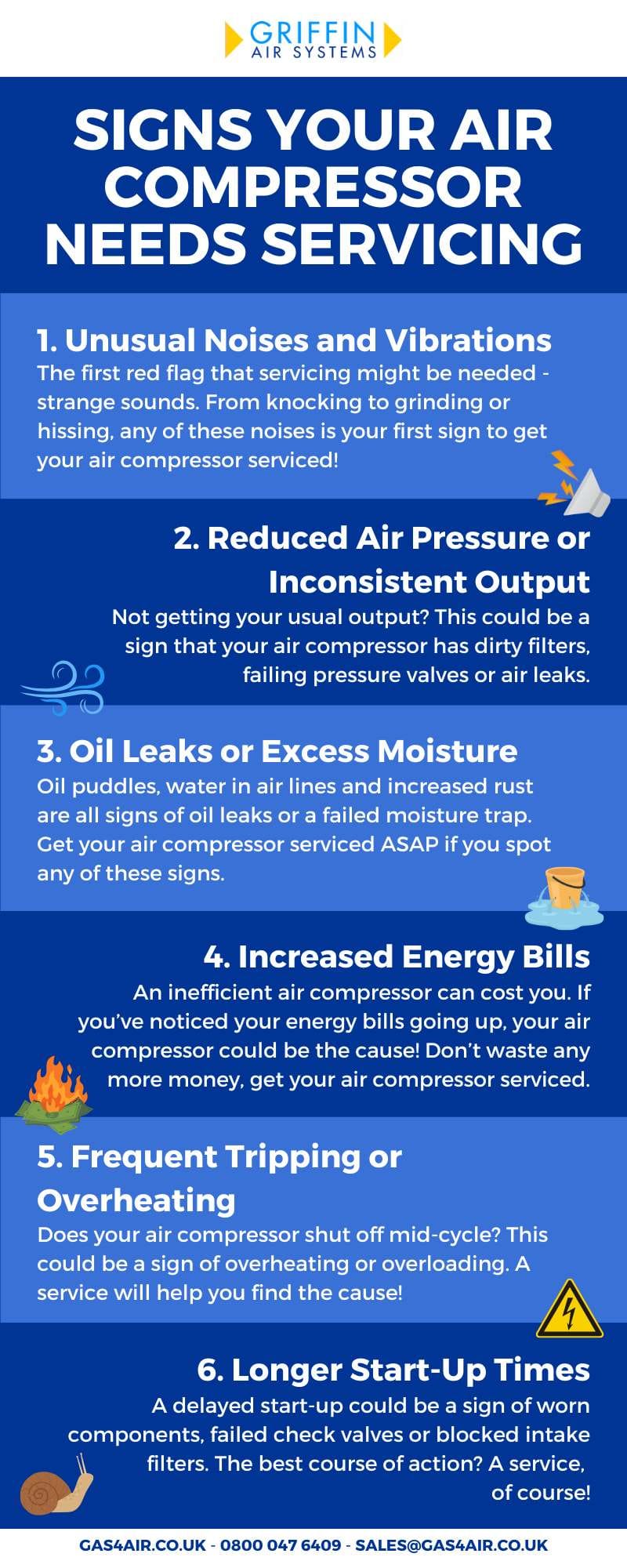

- 1. Unusual Noises and Vibrations

- 2. Reduced Air Pressure or Inconsistent Output

- 3. Oil Leaks or Excess Moisture

- 4. Increased Energy Bills

- 5. Frequent Tripping or Overheating

- 6. Longer Start-Up Times

- Preventative Maintenance Schedule for Air Compressor

- Key Takeaways for Air Compressor Maintenance

1. Unusual Noises and Vibrations

If your air compressor begins making strange sounds – knocking, grinding, or hissing – this is often one of the first red flags that servicing is required. Excessive vibrations could also indicate loose bolts, worn bearings, or misalignment.

Causes of Noise and Vibrations

- Loose mounting bolts or fasteners

- Misaligned components

- Worn internal parts (e.g. valves, pistons)

- Broken fan blades or belts

Ignoring these symptoms could lead to internal component damage. Early detection through regular air compressor maintenance can avoid this.

2. Reduced Air Pressure or Inconsistent Output

If your tools or machinery aren’t performing as they should, your compressor could be failing to maintain the correct pressure levels.

Possible Causes of Inconsistent Air Supply

- Blocked or dirty air filters

- Failing pressure valves or regulators

- Air leaks in the piping or tank

- Worn piston rings or gaskets

Not only will this reduce efficiency, but it could damage pneumatic tools. A prompt air compressor service and repair call-out can often resolve this quickly.

3. Oil Leaks or Excess Moisture

Oil leaks around the compressor are never a good sign. Likewise, if your compressor produces more water than normal or emits rusty moisture, it’s time to act.

What to Look Out For

- Oil puddles near the motor or pump

- Water in air lines or tools

- Increased rust on fittings or hoses

Excessive moisture can result from a failed moisture trap or improperly drained tank. This can contaminate your output and harm downstream equipment.

4. Increased Energy Bills

A neglected air compressor consumes more power to do the same job. If you’ve noticed your energy bills creeping up, your compressor could be operating inefficiently.

Energy Efficiency Warning Signs

- Compressor runs longer to achieve pressure

- System doesn’t shut off when expected

- Air leaks or unbalanced load across machinery

Implementing a preventive maintenance schedule for air compressor systems can significantly improve energy efficiency and reduce costs.

5. Frequent Tripping or Overheating

Modern compressors have built-in thermal protection and circuit breakers. If yours keeps shutting off mid-cycle, it may be overheating or overloaded.

Potential Causes of Overheating

- Dirty cooling fans or fins

- Low oil levels (in oil-lubricated models)

- Blocked air intake vents

- Electrical faults or capacitor failure

This is a serious sign that your unit is under strain and urgently needs servicing. Griffin Air Systems provides fast diagnostics and repair to get your air compressor up and running again.

6. Longer Start-Up Times

Does your air compressor take longer than usual to start? Or perhaps it struggles to build pressure once running? These are signs the unit is struggling and may be close to failing.

Key Reasons Behind Delayed Start-Up

- Failing check valves

- Worn motor components

- Cold weather performance issues

- Blocked intake filters

With regular air compressor preventative maintenance, these issues can be avoided or caught early, extending the lifespan of your equipment.

Preventative Maintenance Schedule for Air Compressor

One of the most effective ways to avoid breakdowns is to stick to a preventative maintenance schedule tailored to your compressor type and usage.

Weekly Maintenance

- Drain condensate from the tank

- Check for leaks or loose fittings

- Clean air intake vents and surroundings

Monthly Maintenance

- Inspect and clean/replacement air filters

- Check oil levels and quality (for oil-lubricated units)

- Examine belts for wear and tension

Quarterly Maintenance

- Inspect pressure relief valve and safety shutoff

- Tighten bolts and electrical connections

- Clean or replace moisture traps

Annual Maintenance (by a qualified technician)

- Complete service inspection

- Oil change and filter replacement

- System recalibration and testing

- Replacement of worn parts (e.g. belts, valves, gaskets)

Book a professional maintenance and service with Griffin Air Systems and we’ll help you stick to your maintenance routine.

Key Takeaways for Air Compressor Maintenance

- Unusual noises, vibrations, or leaks are early signs your compressor needs servicing.

- A drop in air pressure or rising energy bills signals inefficiency that could lead to breakdown.

- Preventative maintenance reduces downtime, increases lifespan, and improves safety.

- Follow a weekly, monthly, and annual maintenance schedule to stay on top of wear and tear.

- Griffin Air Systems offers air compressor service and repair throughout the UK, with fast response times and tailored service plans.

FAQs

How often should I service my air compressor?

The frequency of service depends on the model and usage. Most systems benefit from a basic inspection every month, with a full professional service at least annually. High-demand environments may require quarterly servicing.

What is included in a professional air compressor service?

A full air compressor service and repair includes oil changes, filter replacement, checking pressure valves, leak detection, tightening bolts, cleaning vents, and performance testing. Technicians also look for early signs of wear and suggest repairs before faults occur.

What are the benefits of preventative maintenance for air compressors?

Regular air compressor preventative maintenance helps:

- Extend compressor lifespan

- Reduce energy consumption

- Avoid costly breakdowns

- Maintain tool performance

- Improve workplace safety

Book a Compressor Service with Griffin Air Systems

Your air compressor might not scream for attention until it’s too late—but the signs are always there. By catching problems early through scheduled maintenance and professional servicing, you protect your operations, workforce, and bottom line.

Book your compressor service today or speak to our team to build a preventive maintenance schedule for air compressor units tailored to your needs.