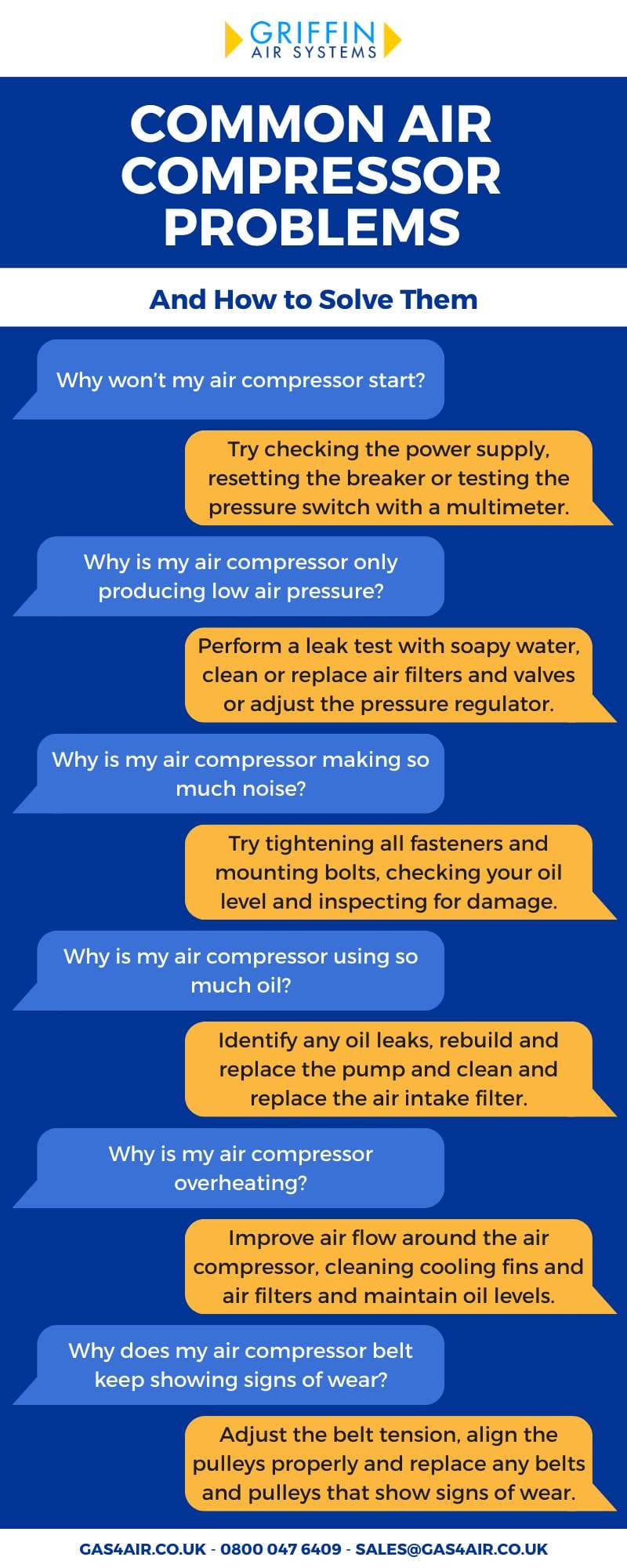

Has your air compressor suddenly stopped working and you don’t know how to fix it? In this guide, we break down the most common air compressor problems and give you simple fixes to help get your air compressor going again. From your air compressor not turning on to overheating issues and damaged components, learn how to fix your air compressor with this Air Compressor Troubleshooting Guide.

- Why Won’t My Compressor Start?

- Why is My Air Compressor Only Producing Low Air Pressure?

- Why Won’t My Air Compressor Stop Running?

- Why is My Air Compressor Making So Much Noise?

- Why is My Air Compressor Using So Much Oil?

- Why is There Oil in My Compressed Air?

- Why is There Moisture in My Compressed Air?

- Why is My Air Compressor Overheating?

- What Do the Electrical Issues with My Air Compressor Mean?

- Why Does My Air Compressor’s Belt Keep Showing Signs of Wear?

- Keep Your Air Compressor at Its Optimum with Griffin

- FAQs

Why Won’t My Compressor Start?

When your air compressor refuses to start, this can put a hold on your entire workflow and cause significant delays. This problem typically stems from electrical issues but there can also be mechanical failures at play. Some possible causes of an air compressor that won’t start include:

- Power supply issues

- Tripped circuit breaker or blown fuse

- Faulty pressure switch

- Motor overload protection activated

- Damaged power cord

- Failed capacitor

Solutions:

- Check your power supply and connections by verifying proper voltage at the outlet and securing all electrical connections.

- Resetting the breaker, replacing the fuse and upgrading the dedicated circuit can help if the problem persists.

- Test the pressure switch with a multimeter and replace it if necessary. There may be corrosion or burned contacts.

- Allow the motor to properly cool before resetting the thermal overload. You should investigate why the overheating has occurred (see Why is My Air Compressor Overheating?).

- Inspect and replace damaged power cords and ensure you only use replacements that meet the manufacturer’s specifications.

- Test and replace the start capacitor if it has failed. This can be identified as a humming sound even when the air compressor isn’t turned on.

Why is My Air Compressor Only Producing Low Air Pressure?

Insufficient air pressure renders many air tools ineffective and can significantly reduce productivity. This common problem has multiple potential causes ranging from simple leaks to serious internal damage. Some common causes of a low pressure output include:

- Air leaks in the system

- Clogged air filters

- Worn or damaged valves

- Incorrect pressure regulator setting

- Undersized compressor for application

- Worn piston rings or cylinders

Solutions:

- Perform a leak test with a soapy water solution and repair leaks by tightening the connections or replacing damaged components.

- Clean or replace air filters regularly according to usage and environmental conditions.

- Inspect, clean or replace intake and discharge valves, looking for carbon buildup, cracks or distortion.

- Adjust pressure regulator setting to match tool requirements while staying within compressor capabilities.

- Ensure the compressor size matches application requirements by calculating your CFM needs for all tools.

- Rebuild or replace the pump if internal components are severely worn. This is often indicated by oil in the discharge air.

Why Won’t My Air Compressor Stop Running?

A compressor that never cycles off wastes energy, increases wear on components and can indicate a significant system problem. Although you might think this is currently a minor issue, it can quickly lead to overheating and premature failure if not addressed immediately. Some possible causes of a compressor that runs continuously include:

- Air leaks in the system

- Faulty pressure switch

- Excessive air demand

- Broken check valve

- Worn piston rings or seals

- Failed unloader valve

Solutions:

- Locate and repair all air leaks by systematically checking connections, hoses and fittings.

- Adjust or replace the pressure switch after verifying cutoff settings with an accurate gauge.

- Reduce air demand or upgrade to a larger compressor by staggering tool usage or investing in a higher capacity.

- Clean or replace the check valve, which often makes a hissing sound when failing.

- Rebuild or replace the pump if internal components are worn, particularly in older units with significant usage.

- Clean, repair or replace the unloader valve, which is critical for proper cycling and restart capability.

Why is My Air Compressor Making So Much Noise?

Abnormally loud operation not only creates an unpleasant work environment but also indicates mechanical problems that could lead to compressor failure. While air compressors are naturally noisy, sudden changes or unusual sounds warrant immediate investigation. The possible causes of excessive noise include:

- Loose components

- Inadequate lubrication

- Worn bearings

- Damaged flywheel or pulley

- Belt issues such as them being slipped or misaligned

- Internal valve problems

Solutions:

- Tighten all fasteners and mounting bolts, paying special attention to pump mounting and belt guards.

- Check and add oil if needed, following manufacturer recommendations for type and level.

- Replace worn bearings when you notice increasing noise levels or grinding sounds.

- Inspect and replace damaged flywheel or pulley, checking for cracks or wobble during operation.

- Adjust, align or replace belts, ensuring proper tension and pulley alignment.

- Rebuild valve assemblies by disassembling the head and inspecting valve plates, springs and seats.

Why is My Air Compressor Using So Much Oil?

Constantly adding oil to your compressor indicates a problem that could affect performance and air quality. Oil consumption issues can range from simple leaks to serious internal damage. Some reasons your air compressor might be consuming too much oil include:

- Oil leaks

- Worn piston rings or cylinder walls

- Clogged air intake filter

- Compressor operated at excessive angle

- Wrong oil type or over filled

- Oil carryover due to high operating temperature

Solutions:

- Locate and repair oil leaks by tightening fittings or replacing worn gaskets and seals.

- Rebuild or replace the pump when internal wear becomes excessive, especially after years of heavy use.

- Clean or replace the air intake filter to ensure proper airflow and prevent vacuum-induced oil carryover.

- Ensure the compressor operates on a level surface according to manufacturer guidelines.

- Use manufacturer-recommended oil types and fill to the correct level marked on the sight glass or dipstick.

- Improve ventilation to reduce operating temperature by ensuring adequate clearance around the unit.

Why is There Oil in My Compressed Air?

Oil contamination in your air supply can damage pneumatic tools, ruin paint applications and contaminate processes requiring clean air. This problem requires prompt attention to prevent disruption to other processes. Things to look out for include:

- Worn piston rings

- A clogged air-oil separator

- Excessive oil in the crankcase

- Compressor running too hot

- Improper oil type

Solutions:

- Rebuild or replace the pump when internal components show significant wear.

- Replace the air-oil separator element according to a maintenance schedule or when oil contamination increases.

- Drain excess oil to the proper level marked on the sight glass or dipstick.

- Improve ventilation around the compressor to maintain proper operating temperature.

- Use only manufacturer-recommended oil designed specifically for air compressors.

- Install or upgrade the air dryer/filter system with coalescing filters designed to remove oil aerosols.

Why is There Moisture in My Compressed Air?

Water in your compressed air system can cause rust in tools and piping, interfere with painting and spraying applications and damage sensitive equipment. This common problem requires proper management rather than elimination, as moisture is an inherent byproduct of air compression. Possible causes of moisture in your compressed air output include:

- Tank not drained regularly

- Failed or missing moisture separator

- High ambient humidity

- Inadequate aftercooler

- Insufficient air dryer capacity

Solutions:

- Drain the tank daily by opening the drain valve until all the water is expelled.

- Install or replace the moisture separator between the compressor and downstream components.

- Install refrigerated or desiccant air dryers matched to your system’s requirements and ambient conditions.

- Upgrade the aftercooler system to ensure air temperature drops enough to condense moisture before distribution.

- Size the air dryer properly for compressor output, considering both flow rate and worst-case humidity conditions.

Why is My Air Compressor Overheating?

Excessive heat accelerates wear, breaks down lubricants and can lead to catastrophic failure. Overheating is particularly dangerous as it creates a compounding problem where damage leads to more heat generation. Possible causes of overheating include:

- Poor ventilation

- Dirty cooling fins

- Low oil-level (for oil-lubricated models)

- Excessive duty cycles

- Clogged air filters

- High ambient temperatures

Solutions:

- Improve airflow around the compressor by ensuring at least 24 inches of clearance on all sides.

- Clean cooling fins and heat exchangers regularly with compressed air or a soft brush.

- Maintain proper oil level by checking it regularly and topping off as needed.

- Reduce the duty cycle or upgrade to a larger unit designed for continuous operation if needed.

- Clean or replace air filters more frequently in dusty environments.

- Add external cooling if needed, such as auxiliary fans or relocation to cooler areas.

What Do the Electrical Issues with My Air Compressor Mean?

Electrical protection devices tripping can indicate an unsafe condition that must be resolved. This problem not only interrupts work but can also signal potential fire hazards or equipment damage. Some possible causes of electrical issues include:

- Undersized circuit

- Multiple devices on the same circuit

- Compressor starting under load

- Failed start capacitor

- Seized pump or motor

- A short in an electrical system

Solutions:

- Use a dedicated circuit with an adequate amperage rating, typically 20-30 amps depending on compressor size.

- Remove other devices from the circuit to ensure adequate capacity for the startup current.

- Ensure the tank pressure is released before startup by confirming the unloader valve functions properly.

- Replace the start capacitor if the motor struggles to start or hums without turning.

- Repair or replace the pump/motor if binding is detected by difficulty in manually turning the flywheel.

- Check wiring for damage and repair as needed, looking for burned, melted, or discolored insulation.

Why Does My Air Compressor’s Belt Keep Showing Signs of Wear?

Premature belt deterioration increases maintenance costs and can lead to unexpected downtime. Properly functioning belts should last 1000-2000 hours of operation under normal conditions. There are many causes of a worn belt including:

- Improper belt tension

- Misaligned pulleys

- Incorrect belt size

- Contamination (oil/grease on the belts)

- Pulley damage

- Excessive vibration

Solutions:

- Adjust the belt tension to manufacturer specifications, typically allowing ½-inch deflection when pressed firmly.

- Align pulleys properly using a straight edge or laser alignment tools across pulley faces.

- Use only recommended belt sizes and types, referencing model-specific information.

- Keep belts clean and free of contaminants by addressing oil leaks and using proper guards.

- Replace damaged pulleys that show signs of wear, chipping, or glazing in the grooves.

- Address vibration issues by checking mounts and balance, ensuring a solid foundation and properly torqued fasteners.

Keep Your Air Compressor at Its Optimum with Griffin

If you have tried these solutions and you still cannot find the solution to your air compressor problems, we can help. As experts in all things air compressor repair, we have handled various scenarios and problems and found solutions for people in your exact position. Get in touch with our air compressor experts today for support and advice in fixing your air compressor. We are on hand 24/7!

FAQs

What are common failures of air compressors?

Common air compressor failures include electrical issues (faulty pressure switches, motor problems, tripped breakers), mechanical failures (worn bearings, broken belts, damaged valves), and system problems like air leaks, excessive moisture and oil contamination. Performance issues such as low pressure output, excessive heat, and continuous running are also often early warning signs of impending component failure. If your air compressor is showing any of these signs, you should troubleshoot using our guide or get in touch with our experts for support in resolving the issue.

What are the three major common electrical failures of compressors?

The three major electrical failures in air compressors are failed start capacitors (preventing motor startup), faulty pressure switches (disrupting automatic cycling), and motor burnout from overload conditions or insufficient cooling. These issues typically manifest as failure to start, intermittent operation, or tripped circuit breakers during operation.

What is the first step in troubleshooting an air compressor failure?

The first step in troubleshooting an air compressor failure is to perform a visual inspection to identify obvious issues like disconnected power, tripped breakers, broken belts, oil leaks, or loose connections. This initial assessment should be followed by a systematic evaluation of symptoms, starting with the simplest and most likely causes before moving to more complex possibilities. It may also be a good idea to call in the experts if there are multiple issues with your air compressor!